What Does a Jewelry Welders Do? Key Facts You Should Know

What does a jewelry welders do? They skillfully join precious metals like gold, silver, and platinum with exacting precision, using tools such as laser welders and micro torches to create flawless, high-strength joints. Jewelry welders interpret technical drawings, apply advanced soldering or welding techniques, and uphold strict safety and quality standards. Their steady hands and deep understanding of metallurgy ensure that each piece is both durable and visually stunning. Whether crafting custom designs or working with gold-plated jewelry, there’s much more to mastering this unique craft than meets the eye.

The Role of a Jewelry Welder in the Industry

Precision defines the work of a jewelry welder, as you’ll be responsible for joining delicate metals and components with exact alignment and minimal distortion.

Your role demands a detailed understanding of jewelry design, as each piece must retain its intended shape and aesthetic. You must interpret technical drawings, follow specifications, and guarantee each joint meets rigorous industry standards for strength and finish.

Working with precious metals like gold, platinum, or silver, you’ll execute welds that are both structurally sound and visually seamless.

Collaboration with designers and gem-setters is essential, as your welds directly impact the final product’s quality.

Ultimately, you serve as the link between artistic vision and durable craftsmanship, ensuring that every piece achieves both beauty and mechanical reliability within industry expectations.

Essential Tools and Equipment Used by Jewelry Welders

While mastering technique is critical, having access to the right tools and equipment forms the backbone of effective jewelry welding.

You'll need essential welding tools such as precision torches, laser welders, and micro-welders, which offer controlled heat application for delicate metals and fine joints. A quality soldering station, complete with a variety of tips, expands your ability to handle complex assemblies.

Supporting jewelry fabrication equipment includes tweezers, magnifying visors, and third-hand tools, all vital for stabilizing intricate pieces during welding. High-grade files, burrs, and abrasive wheels allow for precise finishing.

Safety gear—protective eyewear and proper ventilation—ensures a secure working environment. By investing in specialized essential welding tools and maintaining your jewelry fabrication equipment, you’ll produce durable, beautifully finished pieces with professional consistency.

Common Metals and Materials Worked With

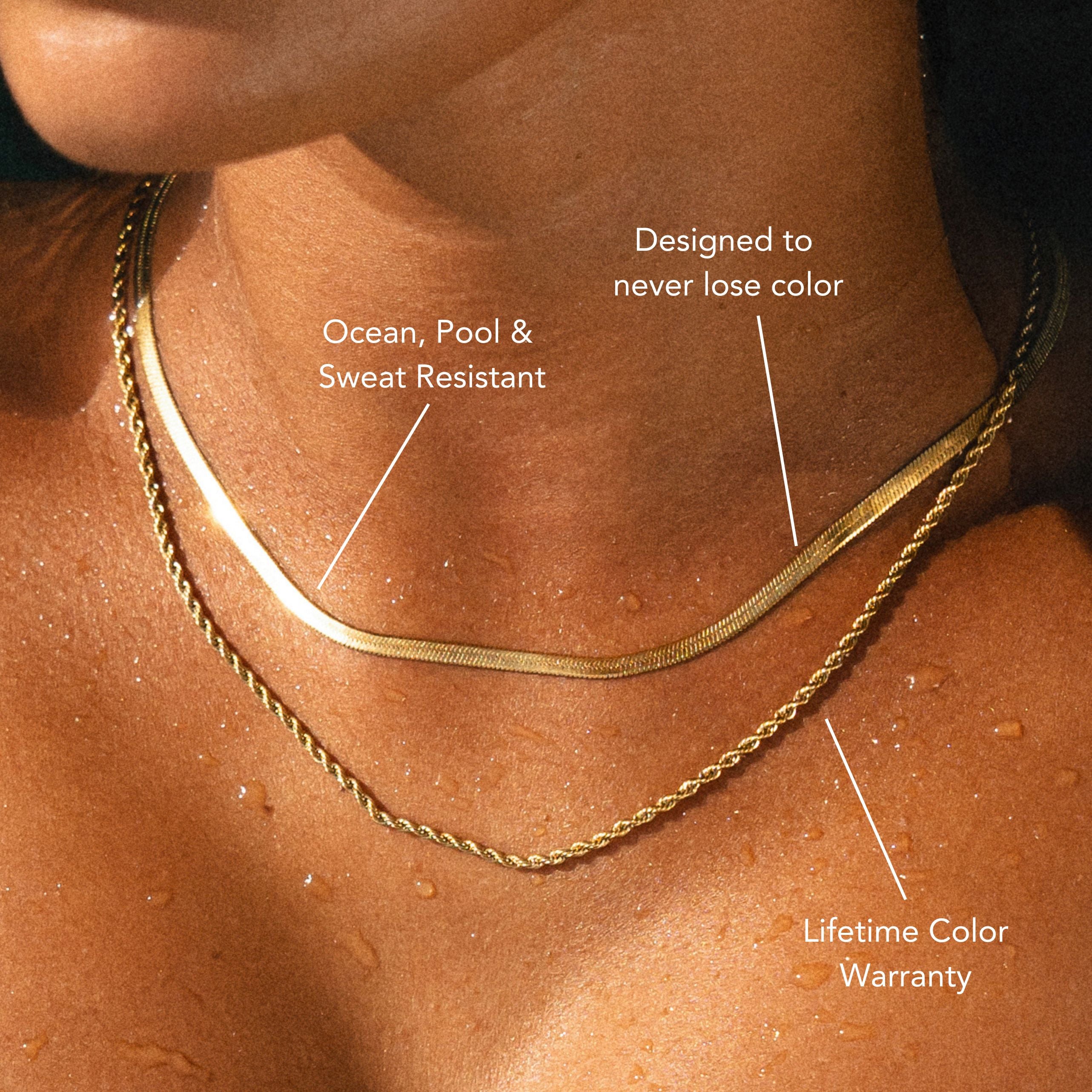

Once you've assembled the proper tools, understanding the metals and materials you'll encounter is fundamental to successful jewelry welding.

You'll frequently work with gold alloys, which vary in karat and color due to differing metal mixtures—such as yellow, white, or rose gold. Each alloy reacts differently to heat, so you must identify the specific type before beginning any work.

Silver is another common material; it requires precise temperature control and clean surfaces for effective silver soldering.

Platinum and palladium, both dense and high-melting metals, demand specialized equipment and knowledge of their unique properties.

Additionally, you may encounter contemporary materials like titanium or stainless steel, which present their own welding challenges.

Mastering these materials guarantees your welds are strong, seamless, and visually appealing.

Techniques and Methods for Welding Jewelry

Several specialized welding techniques form the foundation of professional jewelry fabrication. When you work with precious metals, you'll rely on precise soldering techniques to join components seamlessly.

Mastering temperature control is vital, as overheating can damage delicate stones or alter metal properties. Soldering uses various alloys, each with specific melting points tailored to gold, silver, or platinum.

For intricate repairs or joining small components, laser welding offers unmatched precision. With laser welding, you can focus energy exactly where needed, minimizing heat-affected zones and reducing the risk of distortion.

This method is ideal for working near gemstones or on fine filigree. By choosing the right welding technique, you’ll guarantee strong, nearly invisible joints that preserve the jewelry’s value and aesthetics.

Skills and Training Required for Jewelry Welding

Achieving flawless welds in jewelry fabrication demands more than just familiarity with various techniques. You’ll need a keen eye for detail, steady hands, and strong proficiency in using precision tools.

Formal training, such as apprenticeships or specialized courses, is crucial to develop technical skills and understand the nuances of different metals. Welding certifications—while not always mandatory—can validate your expertise and increase your credibility in the industry.

You should also possess a strong sense of artistic design, as jewelry welding often requires blending intricate aesthetics with structural integrity. Technical knowledge in metallurgy, heat control, and safety protocols is essential.

Challenges Faced in Jewelry Welding

Although advanced tools and refined skills have elevated jewelry welding, the process still presents distinct challenges that demand careful attention.

You must achieve welding precision on intricate, miniature pieces, where even slight misalignment can ruin a design or compromise structural integrity.

Heat management is another critical challenge. Too much heat can damage delicate gemstones, cause discoloration, or deform thin metal components, while insufficient heat won’t create a secure bond.

You’ll also need to contend with the compatibility of different metals, as varying melting points and compositions can complicate the welding process.

Properly controlling the welding environment—such as avoiding contamination and oxidation—is essential to maintain both aesthetic quality and durability.

Mastering these challenges requires constant vigilance, technical skill, and a thorough understanding of materials and tools.

Career Paths and Opportunities for Jewelry Welders

Mastering the complexities of jewelry welding not only sharpens your technical expertise but also reveals a wide array of career opportunities within the industry.

You can pursue positions in high-end jewelry houses, custom design studios, or repair workshops, where your welding proficiency is highly valued. For those seeking career advancement, specializing in laser or micro-welding can set you apart and qualify you for supervisory or design roles.

If you prefer autonomy, there are abundant freelance opportunities—offering repair, restoration, or bespoke fabrication services directly to clients or retailers. With a strong portfolio, you might consult for luxury brands or teach advanced welding techniques.

Whether you choose structured employment or independent contracting, your skills open doors to dynamic, specialized roles throughout the jewelry sector.

Maintenance and Safety Practices in Jewelry Welding

While you focus on perfecting your welding technique, it’s essential to implement rigorous maintenance and safety protocols in your workspace. Regular equipment maintenance guarantees your tools function at peak efficiency and reduces the risk of malfunctions that could compromise your work or safety.

Inspect power sources, torches, and electrodes for wear or damage before each session. Clean contacts and replace consumables as needed. Always calibrate your welding machines according to manufacturer specifications.

Adhering to strict safety protocols protects you from hazards like burns, fumes, and eye injuries. Wear protective eyewear, gloves, and a fitted mask. Confirm your workspace has proper ventilation to minimize exposure to harmful gases.

Secure all flammable materials away from your station. Consistently practicing these steps will safeguard both your work quality and personal well-being.

Frequently Asked Questions

Can Jewelry Welders Repair Antique or Heirloom Pieces?

You can trust jewelry welders to expertly handle antique restoration and heirloom preservation. They'll use precision welding techniques, specialized tools, and careful material matching to repair delicate, valuable pieces while maintaining the original integrity and historical craftsmanship.

Are Jewelry Welders Required to Have Insurance?

You're not legally required to have insurance as a jewelry welder, but it's smart to cover welding risks. Common insurance types include liability, property, and professional indemnity insurance, protecting you against potential damage, theft, or customer claims.

How Long Does a Jewelry Welding Project Usually Take?

The duration of your jewelry welding project depends on project complexity and chosen welding techniques. Simple repairs may take under an hour, while intricate custom pieces might require several hours or even days to achieve precise, high-quality results.

Is Jewelry Welding Environmentally Friendly?

You can make jewelry welding environmentally friendly if you use sustainable practices and choose eco friendly materials like recycled metals. Avoid harsh chemicals, minimize waste, and select energy-efficient welding tools to further reduce your environmental impact.

Conclusion

As a jewelry welder, you'll need precision, technical skill, and a deep understanding of metals and equipment. Your role goes beyond simple repairs—you'll craft, restore, and assemble delicate pieces using advanced techniques and specialized tools. With the right training and safety practices, you can navigate the challenges of the trade and access various career opportunities. Mastering jewelry welding means consistently producing high-quality, durable work that meets both artistic and structural standards in the industry.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.