How to Polish Silver Chain Properly

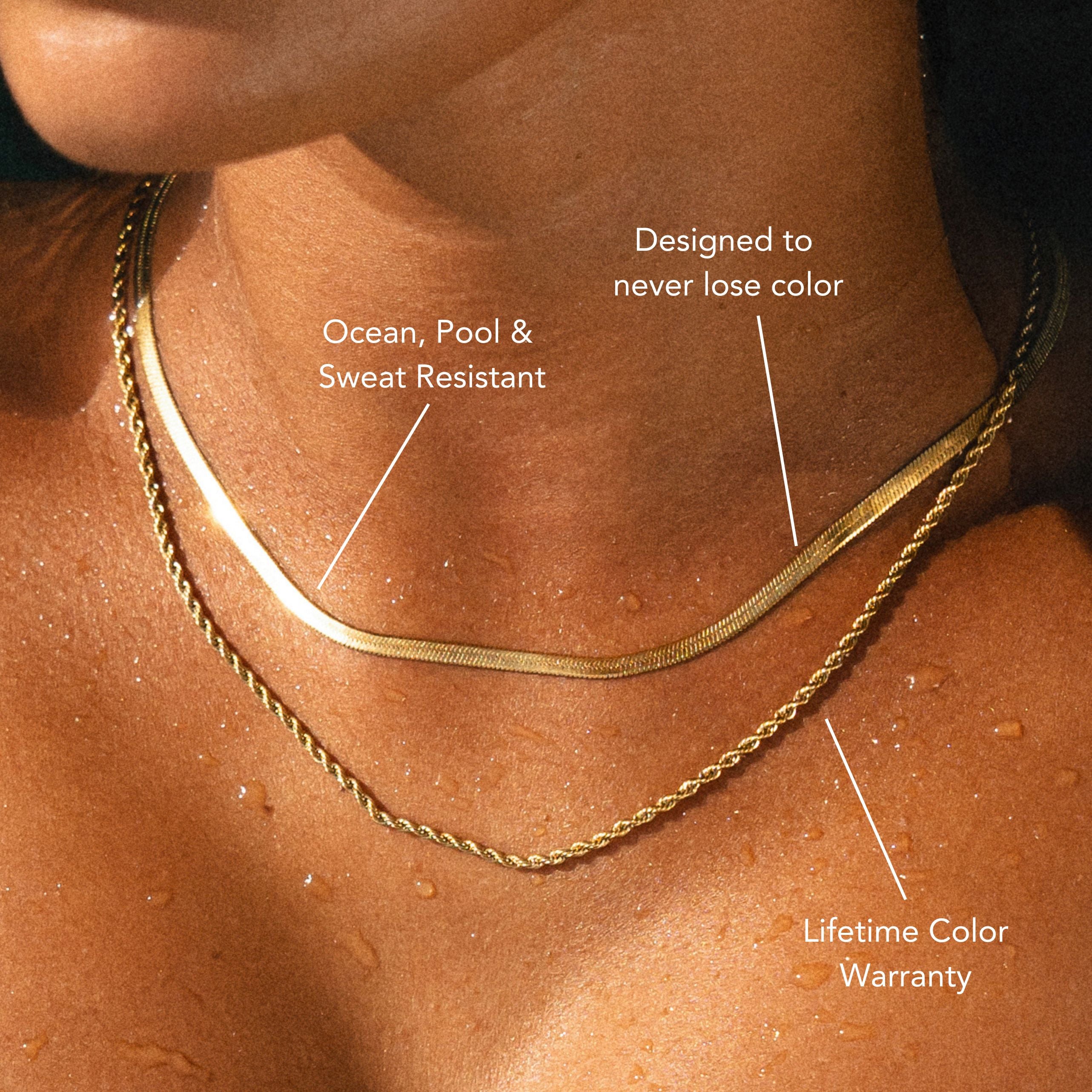

How to polish silver chain? Start by identifying the metal—sterling, coin, fine, or plated—using hallmarks and a quick magnet check. Pre-clean in lukewarm water with pH-neutral soap, then rinse and dry thoroughly. Wear nitrile gloves and apply a non-abrasive silver cream with a microfiber cloth, polishing in light, straight strokes while supporting flexible links on a soft pad. Avoid rotary tools, ammonia, and harsh abrasives—especially on hollow chains, textured finishes, gemstones, or rhodium plating. Rinse, pat dry, and buff with a lint-free cloth. For low-maintenance alternatives designed to resist tarnish, explore our Waterproof Necklaces collection. Store silver with anti-tarnish strips—remember, even gentle polishing removes microns, so technique matters.

Identify Your Silver and Finish

Start by confirming what you’re working with: solid sterling silver (typically stamped “925” or “Sterling”), coin silver (“900”), fine silver (“999”), or silver‑plated base metal (marks like “EPNS,” “Silverplate,” or brand hallmarks).

Verify silver purity with hallmarks and, if unclear, test discreetly using a magnet (nonmagnetic) and dimensions versus weight. Note chain types—cable, curb, rope, box, wheat, Figaro, snake—because geometry dictates abrasion risk and snag potential.

Inspect the surface finish: bright‑polished, satin/brushed, antiqued/oxidized recesses, rhodium‑plated, or lacquered.

Rhodium and lacquers require non‑abrasive treatment; plated silver tolerates only minimal friction. Identify soldered versus open links and any weak jump rings.

Locate gemstones, enamel, or inlays that can’t handle aggressive contact. Document defects, pits, and prior repairs so you don’t over‑thin susceptible sections during polishing.

Gather Safe Tools and Products

Two categories matter now: non‑abrasive cleaners for tarnish removal and controlled‑abrasive tools for refining scratches.

Assemble safe cleaning products first: pH‑neutral silver creams or gels with thiourea‑free formulations, ammonia‑free dish soap for pre‑wash, and distilled water to avoid mineral spotting.

Add lint‑free microfiber cloths and 100% cotton swabs for precise application. For silver polishing tools, select treated polishing cloths with anti‑tarnish compounds, foam applicators, and soft horsehair or goat‑hair brushes to reach links without marring.

For controlled abrasion, stock high‑grit options only: jeweler’s rouge or alumina compounds, 3000–8000 grit micromesh pads, and non‑woven polishing wheels rated fine or ultrafine.

Use nitrile gloves to prevent skin oils transferring sulfur. Keep a silicone‑lined mat, task lighting at 90+ CRI, and resealable bags to isolate cleaned chain from reactive air.

Inspect for Gemstones and Platings

Before you polish, verify what you’re working on: identify any gemstones, coatings, or plated finishes that dictate safe methods.

Examine the chain under strong light and 10x magnification. Look for bezel or prong-set stones, glued cabochons, or inlays; note porosity, fractures, and doublets—these determine solvent and pressure limits in gemstone care.

Determine metal type with hallmarks: “925” or “Sterling” for solid silver; “GP,” “GEP,” “HGE,” “RGP,” or “Vermeil” for plating. Assess wear at high-friction points to gauge plating thickness and plan plating maintenance.

Test discreetly with a cotton swab: if color transfers from a gold-toned area to white, you’ve got thin plating.

Map sensitive zones to avoid abrasives, heat, ultrasonic exposure, or ammonia near stones and plated sections.

Pre-Clean to Remove Oils and Grime

Even with delicate pieces, remove surface oils and loose grime first to prevent scratching during polishing.

Start with a lukewarm rinse to float off dust. Perform oil removal using a drop of pH‑neutral dish soap in water (about 1:100). Agitate the chain gently in the solution for 60–90 seconds to break sebum bonds. Use a soft, lint‑free microfiber or a baby‑soft toothbrush to reach crevices; don’t scrub aggressively.

Rinse thoroughly under lukewarm running water to clear surfactants and particulate. Pat dry with a clean microfiber, then air‑dry on a rack to prevent trapped moisture in links.

If residues persist, spot-treat with isopropyl alcohol (70%) on a swab—quick, targeted application only. Avoid ammonia, bleach, toothpaste, or abrasive cleaning agents that etch silver. Confirm the chain is fully dry before any further work.

Choose the Right Polishing Method by Chain Style

With the chain clean and fully dry, match your polishing approach to its construction to avoid wear and distortion. Assess chain styles by link geometry and rigidity.

For solid, rigid profiles (curb, figaro, mariner), use controlled cloth-based polishing techniques with linear strokes along the link plane to preserve edges.

For flexible, articulated types (rope, wheat, singapore), minimize torsion; support the chain on a soft pad and polish in short segments to prevent kinking.

For hollow or lightweight chains, avoid aggressive compounds and motorized wheels; choose low-abrasive media and minimal pressure.

For textured or diamond-cut links, reduce stroke length and keep abrasives off recesses to maintain facets.

For oxidized or antiqued finishes, target only high points, protecting patina with masking.

Hand-Polishing Technique for Minimal Abrasion

Work deliberately to remove tarnish while preserving metal. Use controlled hand techniques that limit pressure and stroke length. Place the chain flat on a clean, padded surface to prevent kinking.

Select nonabrasive polishing products: a quality silver cream or micro-abrasive paste rated for sterling. Pre-test on an inconspicuous link. Charge a soft cotton swab or microfiber with a rice-grain amount; don’t overload.

Stabilize the chain with your non-dominant hand. With your dominant hand, make short, linear strokes along the link’s grain, not across it. Rotate the chain frequently to access interior curves and seams. Refresh the applicator often to avoid dragging spent compound.

For stubborn spots, pinch a single link between two swab tips and glide lightly. Stop once tarnish lifts; excessive passes thin silver.

Rinsing, Drying, and Lint-Free Buffing

Flush away residue under a gentle, lukewarm stream, keeping the chain supported to prevent flex stress.

Use controlled rinse techniques: orient links so water flows along, not across, the chain; pulse the stream to dislodge compound from crevices; avoid high pressure that can flare jump rings.

Rotate the clasp area separately to clear hinge pockets.

Transition to drying methods immediately. Blot, don’t rub, with a clean, laboratory-grade lint-free wipe.

Press along the chain in sections to wick moisture from capillaries between links. Use compressed air (oil- and moisture-free) at low PSI to expel trapped water; keep the nozzle 10–15 cm away.

Finish with a lint-free buff. Use a microfiber polishing cloth with a tight weave; apply linear strokes following the chain’s axis, minimal pressure, and frequent cloth rotation.

Preventing Tarnish and Storing Properly

Two factors drive tarnish: sulfur exposure and humidity. For effective tarnish prevention, control both.

After polishing, verify the chain is fully dry; residual moisture accelerates sulfide formation. Store silver in airtight conditions: use zip-top polyethylene bags or dedicated anti-tarnish pouches with active adsorbents (activated charcoal or silica gel). Replace desiccants when indicator cards show saturation.

Isolate silver from sulfur sources—rubber bands, felt, wool, latex, newsprint, and certain wooden boxes.

Practice proper storage by coiling the chain loosely to avoid kinks, then place it in a soft, non-abrasive sleeve to prevent frictional micro-scratches. Purge bag air before sealing to reduce oxygen and humidity.

Wear after cosmetics cure; remove before swimming, hot tubs, or cleaning agents. Inspect monthly and refresh protective materials.

Troubleshooting Heavy Tarnish and Stubborn Spots

Even with airtight storage and desiccants, older chains or neglected pieces can develop dense, black silver sulfide layers that standard polishing cloths won’t lift.

Begin with a controlled tarnish removal bath: use a commercial thiosulfate-based dip, submerge for 5–15 seconds, agitate gently, then rinse in deionized water and dry. Inspect under bright light.

For stubborn stains in crevices, switch to a mild ammonia solution (1:10 with water) and a soft-bristle brush; work along links, not across them.

Escalate to a micro-abrasive polish (alumina or calcium carbonate) applied with a microfiber applicator, using straight strokes, minimal pressure. Avoid rotary tools on delicate chains.

If pitting persists, consider professional ultrasonic cleaning. After restoration, neutralize residues with a final rinse, dry thoroughly, and re-seal with anti-tarnish strips.

Frequently Asked Questions

How Often Should I Polish a Regularly Worn Silver Chain?

Polish it every 4–6 weeks. Adjust polishing frequency based on tarnish level and environment. Between sessions, prioritize chain care: rinse after sweat, dry thoroughly, store airtight, use anti-tarnish strips, and clean gently to avoid abrasive wear.

Can Ultrasonic Cleaners Damage Delicate Chain Links?

Yes, ultrasonic cleaners can damage delicate chain links. You should assess chain link durability, soldered joints, and gemstones first. For ultrasonic cleaner safety, use mild solutions, short cycles, suspended baskets, and avoid severely worn, hollow, or micro-cracked links to prevent fatigue.

Is Professional Polishing Necessary for Heirloom or Antique Chains?

Yes, especially for fragile or valuable pieces. You should seek a professional assessment to avoid metal loss, over-polishing, or stone damage. Experts use controlled techniques and documentation that support heirloom preservation, structural integrity, and long-term value retention.

Will Polishing Remove Intentional Oxidized or Matte Finishes?

Yes, aggressive polishing can strip intentional finishes, softening oxidized recesses and brightening the surface, diminishing a matte appearance. Use mild agents, hand techniques, and masking to preserve patina; test inconspicuous areas and specify finish retention to professionals.

How Do Temperature and Humidity Affect Tarnish Rate on Silver Chains?

Temperature and humidity accelerate tarnish by promoting sulfur reactions and moisture-driven ion transport. You mitigate environmental factors with airtight storage, desiccants, anti-tarnish strips, and body-oil barriers. Avoid bathrooms, sweat, and heat. Rotate wear, dry thoroughly, and deploy consistent tarnish prevention methods.

Conclusion

You’ve identified your silver, inspected it, and used the least abrasive method that fits your chain’s construction. Keep finishing steps tight: rinse thoroughly, pat dry, then buff with a clean, lint‑free cloth. Store pieces in anti-tarnish pouches with desiccant, and avoid sulfur, humidity, and cosmetics. For heavy tarnish, escalate methodically: targeted silver polish, then treated cloths, then a professional ultrasonic or re-plate if plated. Maintain a light, regular clean to prevent cumulative abrasion and preserve luster.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.