What's the Best Size Jump Ring for Jewelry?

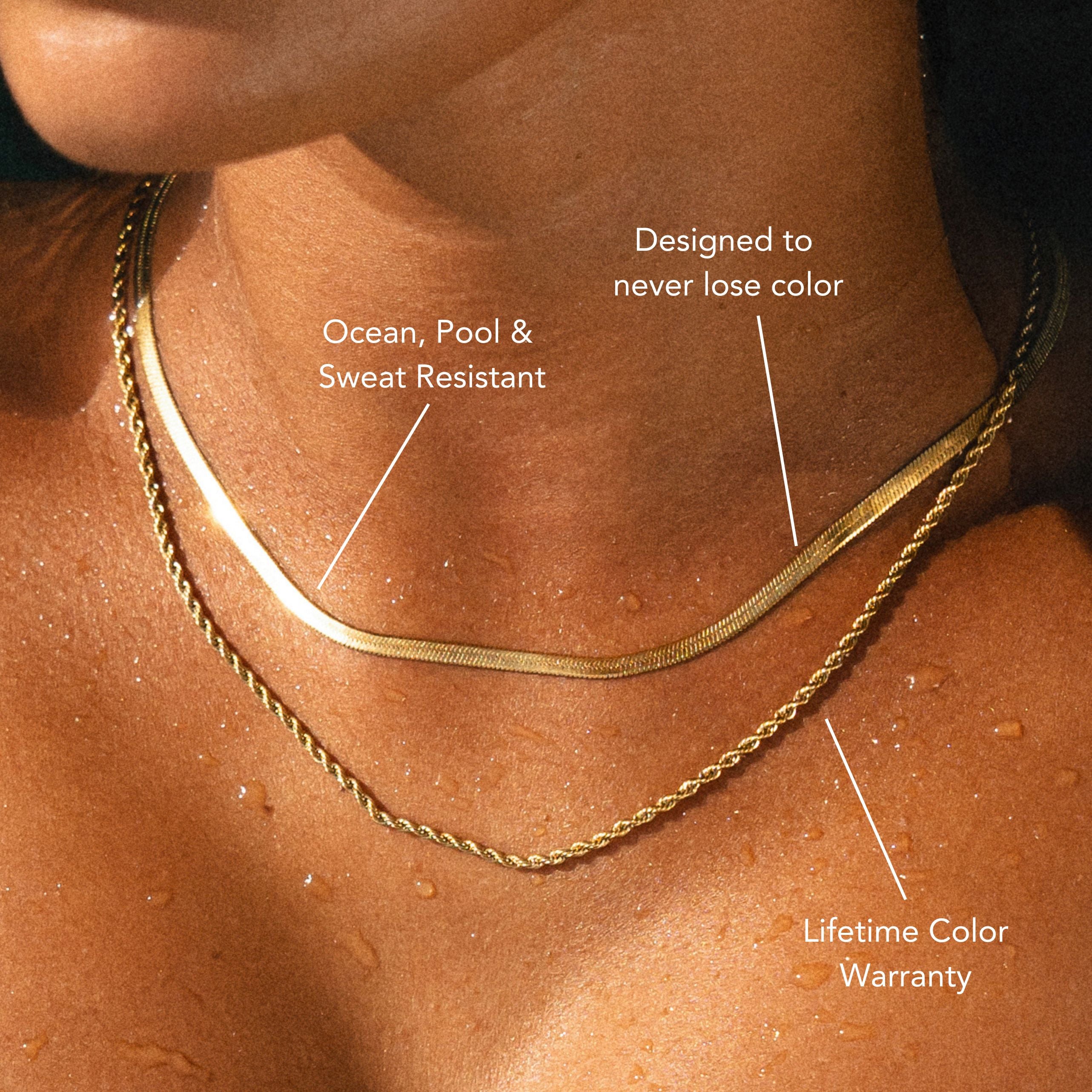

Wondering what’s the best size jump ring for jewelry? It really depends on your specific project. In general, 18–20 gauge rings with a 3–6mm inner diameter work well for most designs. Go with smaller, thinner rings (like 20 gauge, 3–4mm) for delicate pieces or earrings. For bracelets and necklaces, 18 gauge rings with a 5–6mm diameter offer extra strength. Always consider the weight and movement of your materials—and double-check whether you're measuring the inner or outer diameter. If you're creating durable pieces like those in our Waterproof Jewelry collection, choosing the right size is even more important for a secure, long-lasting connection.

Understanding Jump Ring Sizes: Diameter and Gauge

When selecting jump rings for jewelry making, you need to contemplate two key measurements: diameter and gauge.

Diameter refers to the internal width of the ring, typically measured in millimeters, which determines the opening size for attaching components. Gauge denotes the wire thickness, with lower numbers indicating thicker wire.

In jump ring terminology, you’ll see gauges like 18, 20, or 22, each suited for different jump ring applications. For instance, a heavier gauge offers more strength for securing clasps, while a finer gauge works for delicate connections.

Understanding these dimensions lets you balance function and aesthetics. Always match the ring’s diameter and gauge to your project’s stress points and the items being connected, ensuring durability and a seamless finish in your jewelry designs.

Matching Jump Rings to Different Jewelry Types

Once you understand how diameter and gauge affect jump ring strength and compatibility, you can confidently match the right jump ring to each jewelry type.

For earrings, opt for lightweight jump ring styles with smaller diameters and thinner gauges—these maintain a delicate appearance and prevent unnecessary weight.

For bracelets and anklets, choose sturdy, closed jump rings in medium gauges to handle frequent movement and stress.

Charms or pendants benefit from heavier gauge jump rings, ensuring secure attachment and longevity.

Consider jump ring finishes to coordinate with your design—polished, matte, or antiqued finishes can enhance or contrast metal tones.

Specialized jump ring styles, such as oval or textured, provide unique design functionality and visual interest, ensuring both practical integrity and aesthetic cohesion in your jewelry pieces.

Best Jump Ring Sizes for Necklaces

Selecting the ideal jump ring size for necklaces requires careful consideration of both gauge and inner diameter to ascertain durability and seamless integration with chain links and clasps.

For most necklace styles, a 20 to 18 gauge jump ring offers the right balance of strength and subtlety. When working with delicate chain types such as cable, box, or rolo, opt for a 20 gauge jump ring with an inner diameter between 3mm and 4mm for secure, unobtrusive attachment.

For heavier or statement necklace styles, use an 18 gauge jump ring with a 5mm to 6mm inner diameter to accommodate larger end links and provide additional stability.

Always match the jump ring metal to your chain type to prevent galvanic corrosion and ascertain cohesive aesthetics.

Ideal Jump Ring Sizes for Bracelets

Several factors determine the ideal jump ring size for bracelets, including gauge, inner diameter, and the specific bracelet design.

When selecting jump rings, consider the weight and thickness of the bracelet chain or components. For most bracelet designs, a 18 to 20 gauge wire provides sufficient strength without excessive bulk.

Choose an inner diameter between 4mm and 6mm for standard chains, which guarantees secure connections yet maintains flexibility. Heavier bracelets or those with larger links may require thicker gauges, such as 16 gauge, and a slightly larger inner diameter.

Always match the jump ring size to the bracelet design to prevent gaps or overstressing the ring. Properly sized jump rings enhance both the durability and aesthetics of your finished bracelet piece.

Choosing Jump Rings for Earrings

While bracelets require sturdy jump rings to handle movement and weight, earrings demand a more delicate balance between strength and subtlety.

When choosing jump rings for earrings, consider both earring styles and earring weight. Lightweight studs or drops benefit from 24–22 gauge jump rings, which offer minimal visual impact while maintaining sufficient durability.

For heavier dangles or statement earrings, opt for 20–18 gauge jump rings to prevent distortion and accidental opening. Inner diameter matters, too—select 3–5mm for small, discreet connections or 6–8mm for bolder, more decorative links.

Always match the jump ring’s metal to your findings to guarantee seamless integration and prevent galvanic corrosion. Properly closed, well-sized jump rings support the structural integrity and aesthetic of all your earring creations.

Selecting Jump Rings for Charms and Pendants

Because charms and pendants often serve as focal points in jewelry design, you’ll need jump rings that balance security with fluid movement. For reliable charm attachment, select jump rings with an inner diameter 1–2mm wider than the charm’s loop. This guarantees the charm swings freely but won’t slip off.

Choose wire gauges between 18 and 20 for most pendants; they’re strong enough to prevent accidental opening yet slim enough to fit standard pendant bails or charm holes. For heavier pendants, opt for thicker gauges (16 or 18), while lightweight charms suit finer gauges.

Always verify the jump ring’s closure is flush and secure to avoid gaps. Correct sizing for pendant hanging prevents tangling and supports the overall durability and longevity of your jewelry piece.

Materials and Finishes: How They Affect Size Choice

Although jump ring size is critical, the material and finish you choose also directly influence your selection. Different material types—such as sterling silver, gold-filled, stainless steel, or brass—have unique properties that affect the ideal inner diameter and wire gauge.

For example, softer metals like sterling silver may require a thicker gauge to maintain shape, while harder materials like stainless steel can allow for thinner wire without compromising structural integrity.

Finish options, including polished, matte, antiqued, or plated surfaces, impact the overall look and feel of your jewelry. You’ll want to match jump ring finishes to other components for visual cohesion.

Additionally, certain finishes add slight thickness to the wire, so always verify inner diameter measurements to confirm a proper fit with your design elements.

Strength and Durability Considerations

To guarantee your jewelry withstands daily wear, you need to take into account both the wire gauge and the overall diameter of your jump rings.

The wire gauge directly impacts strength requirements; thicker gauges like 16 or 18 offer more structural integrity for heavy or high-movement pieces, while finer gauges such as 20 or 22 suit lightweight or delicate projects.

Durability factors also include the jump ring’s inside diameter—larger diameters are more prone to deformation under tension, especially if paired with thin wire.

For components bearing significant stress, choose a smaller inside diameter and heavier gauge to minimize distortion and accidental opening.

Always assess the specific load and movement expected in your design to match jump ring dimensions to your project’s durability needs.

How to Measure and Open Jump Rings Properly

Precision matters when working with jump rings, so accurate measurement and proper handling are essential for secure, professional-looking jewelry.

To measure jump rings, use precise measuring tools like digital calipers or a jeweler’s gauge to determine both the inner diameter (ID) and wire gauge. Always validate these dimensions before use, as even minor discrepancies can affect fit and strength.

For opening jump rings, employ two pairs of flat-nose or chain-nose pliers. Hold each side of the ring and apply a gentle, twisting motion—never pull the ends apart, as this can distort the shape and compromise structural integrity.

Mastering these jump ring techniques guarantees connections remain discreet and durable, maintaining both the aesthetic and mechanical quality of your jewelry pieces.

Common Mistakes to Avoid When Choosing Jump Rings

While jump rings seem straightforward, many jewelry makers overlook factors that directly impact their function and durability.

One of the most common sizing errors involves selecting rings with a gauge too thin for the project’s weight, leading to distortion or breakage.

Another frequent mistake is confusing the inside diameter (ID) with the outside diameter (OD); always confirm which measurement a supplier uses to avoid mismatched components.

Don’t fall for jump ring misconceptions like “one size fits all”—different designs require specific sizes and strengths.

Overlooking the type of metal or finish can also result in tarnishing or weak connections.

To guarantee a secure hold, always match the jump ring’s gauge and diameter to your project’s components and intended use, prioritizing structural integrity over aesthetics.

Frequently Asked Questions

Can Jump Rings Be Soldered Closed for Extra Security?

Yes, you can solder jump rings closed for extra security. When you use proper soldering techniques, you greatly enhance jump ring durability, eliminate potential gaps, and guarantee a permanent, seamless closure essential for high-stress jewelry applications.

Are Hypoallergenic Jump Rings Available for Sensitive Skin?

You’ll find hypoallergenic jump rings made from materials like surgical stainless steel, titanium, and niobium. These options minimize skin sensitivities because they’re nickel-free and corrosion-resistant, making them ideal if you’re crafting jewelry for sensitive skin.

How Should I Store Jump Rings to Prevent Tarnishing?

To maximize tarnish prevention, you should use airtight storage solutions like anti-tarnish bags or containers with silica gel packets. Avoid humidity and direct sunlight, as these accelerate oxidation, compromising your jump rings’ luster and structural integrity.

What Tools Are Best for Opening and Closing Jump Rings?

You'll get the best results using two pairs of pliers—flat-nose and chain-nose are ideal pliers types. For precise jump ring techniques, grasp each side and twist gently in opposite directions, never pull apart, preventing distortion.

Can I Color Coordinate Jump Rings With My Jewelry Pieces?

You can absolutely color coordinate jump rings with your jewelry pieces. Apply color theory to select complementary or analogous hues, and consider matching or contrasting metal finishes—like sterling, gold-filled, or anodized aluminum—for a cohesive, professional aesthetic.

Conclusion

Choosing the right jump ring size means balancing diameter, gauge, and material for your specific project. Always match the ring’s strength to your jewelry’s weight—thicker gauges for heavier pieces, smaller diameters for discreet joins. Don’t forget that different materials and finishes can affect durability and flexibility. Measure with precision, use proper opening techniques, and avoid common sizing errors. With careful selection, you’ll guarantee secure, professional-quality connections that enhance your jewelry’s design and longevity.

コメントを書く

このサイトはhCaptchaによって保護されており、hCaptchaプライバシーポリシーおよび利用規約が適用されます。