Best Metal for Jewelry Making: Strongest Options Ranked

Finding the best metal for jewelry making starts with measured performance, not guesswork. Tungsten carbide leads in scratch resistance (≈1,600–2,400 HV) but can’t be resized, making it ideal for set-and-forget pieces. Titanium alloys deliver an exceptional strength-to-weight ratio with outstanding corrosion resistance and secure settings, while 316L stainless steel offers affordable toughness, low maintenance, and skin-friendly wear—qualities you’ll often find in Hypoallergenic Jewelry. Among precious metals, 14k–18k gold balances hardness with workability, palladium is lightweight and naturally white, and Argentium silver outperforms traditional sterling with higher hardness and better tarnish resistance. Next, see how these rankings translate into smart, real-world jewelry choices.

How We Ranked Jewelry Metals by Strength and Durability

Although aesthetics matter, we ranked metals primarily by mechanical performance: hardness, tensile strength, yield strength, wear resistance, and corrosion behavior.

You need metrics, not myths, so we standardized tests and sources. We prioritized Vickers hardness for scratch resistance, ultimate tensile strength for load-bearing, and 0.2% offset yield strength for deformation control.

We assessed tribological wear data and pitting/crevice resistance in chloride environments to gauge daily longevity.

You’ll see rankings grounded in published material data sheets, ASTM test results, and peer-reviewed studies.

We normalized values to comparable units, then weighted metal properties by real-world durability factors: ring abrasion, clasp stress, and sweat exposure.

We excluded coatings and focused on bulk alloys at typical jewelry tempers.

Finally, we validated results against bench feedback—resizing behavior, prong retention, and polishing response.

Tungsten Carbide: Maximum Hardness for Scratch Resistance

Despite its ceramic-like brittleness, tungsten carbide sets the benchmark for scratch resistance in jewelry, delivering Vickers hardness typically 1,600–2,400 HV—an order of magnitude above 14k gold (120–200 HV) and well beyond hardened stainless steels (~500–700 HV).

You gain exceptional wear resistance; rings, bands, and inlay edges maintain crisp geometry for years. Tungsten properties include high elastic modulus (~550–700 GPa) and excellent abrasion resistance, but limited fracture toughness. Expect superb polish retention, low coefficient of friction, and minimal surface wear under daily contact with metal, glass, or stone.

For jewelry applications, confirm cobalt-free binders (nickel or palladium) to reduce skin reaction risk and mitigate corrosion staining.

Size carefully—carbide’s low ductility prevents resizing. Prioritize beveled profiles and chamfered edges to reduce chipping. Choose certified hardness, precise grit finishing, and tightly sintered micrograin grades for maximum longevity.

Titanium and Ti Alloys: Strength-to-Weight Standouts

While light on the hand, titanium delivers outsized performance for jewelry, pairing a density of ~4.5 g/cm³ (about 60% of stainless steel’s) with high specific strength and excellent corrosion resistance.

You get rings and bracelets that feel minimal yet endure daily wear. Commercially pure grades (e.g., Grade 2) offer biocompatibility and excellent passivation; beta and alpha-beta alloys (notably Ti-6Al-4V) add higher tensile strength and fatigue resistance—key ti alloy benefits for thin profiles and tension settings.

You can anodize titanium for stable interference colors, expanding titanium applications beyond gray to vivid hues without pigments.

It’s nickel-free, reducing allergenic risk. Though machining is demanding, precision CNC and laser techniques produce crisp geometries and secure stone seats.

For lightweight durability and modern aesthetics, titanium excels.

Stainless Steel (316L): Affordable, Tough, and Low Maintenance

Prefer a metal that shrugs off daily wear without the premium price of aerospace alloys? 316L stainless steel delivers.

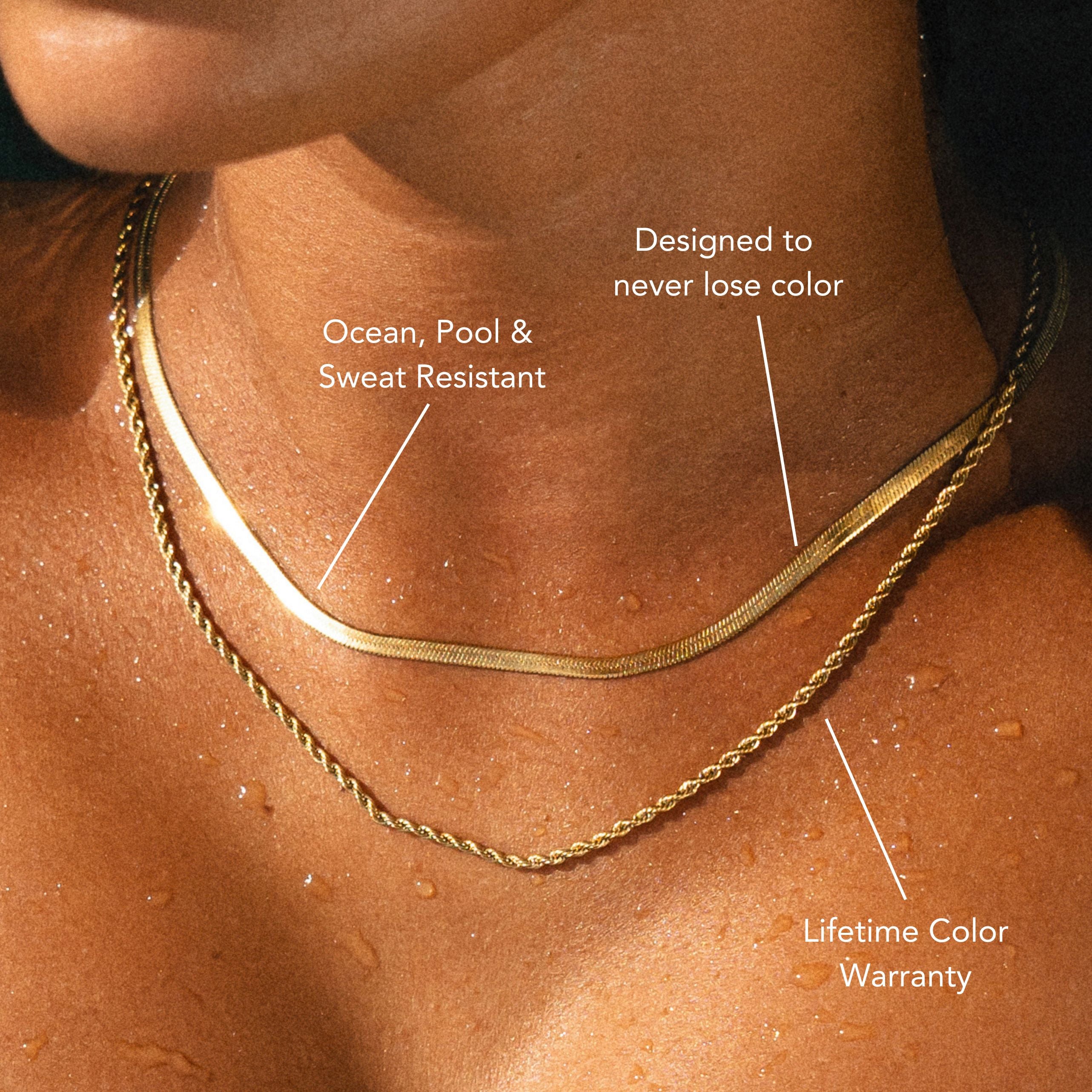

You get high tensile strength, excellent yield behavior, and superior corrosion resistance due to molybdenum and low carbon content. It resists pitting from sweat and seawater, so finishes stay crisp. The stainless steel benefits extend to hypoallergenic performance for most wearers, thanks to tightly bound nickel and low release rates.

You can expect minimal jewelry care: wash with mild soap, rinse, dry, and occasionally polish with a microfiber cloth. It won’t tarnish, and it shrugs off scratches better than softer precious metals.

It’s readily cast, machined, and laser engraved, enabling clean geometry and secure settings. For daily-wear rings, chains, and bracelets, 316L balances durability, cost efficiency, and low maintenance.

Platinum and Iridium Alloys: Dense, Durable Luxury

Because density and ductility matter in fine settings, platinum–iridium alloys deliver true luxury with engineering rigor. You get high density (~21.5 g/cm³) for reassuring heft and superior prong security.

Key platinum properties include exceptional corrosion resistance, hypoallergenic performance, and a high melting point that tolerates torch work and Hall-effect soldering margins. Adding 5–10% iridium raises hardness and yield strength, sharpening edge retention on micro-pavé and channel walls.

You’ll notice iridium benefits in improved wear resistance and reduced deformation under daily load. The alloy cold-works cleanly, burnishes well, and maintains tight tolerances after polishing because metal displacement exceeds metal loss.

Solder compatibility is predictable, and porosity risk is low with proper casting parameters. Choose it when you need longevity, gemstone safety, and premium tactile weight.

Gold Alloys (10k–18k): Balancing Hardness, Color, and Workability

Even as karat values shift gold’s purity, you can engineer 10k–18k alloys to hit specific targets for hardness, color, and bench behavior.

At 10k (41.7% gold purity), higher base-metal content boosts yield strength and scratch resistance, making it practical for high-wear settings.

At 14k, balanced alloy composition delivers reliable hardness with good ductility for stone setting and repair.

At 18k (75% gold), you gain richer color and corrosion resistance while maintaining adequate hardness if you choose silicon- or zinc-modified formulations.

Tune color via copper (red/rose), silver (green), or mixed Cu/Ag (yellow).

Control grain size and spring-back with controlled additions (e.g., nickel-free deoxidized systems), and specify heat-treatment schedules to optimize hardness.

Document Vickers hardness targets and solder compatibility to guarantee consistent shop performance and durability.

Palladium and White Gold: Light, Wear-Resistant Premium Options

Stepping from color-tuned yellow alloys to white metals, you’ll find palladium and modern white gold offer premium brightness, low weight, and strong wear performance.

Palladium properties include high hardness-to-weight ratio, natural white color (no rhodium needed), excellent corrosion resistance, and hypoallergenic behavior. It’s around 40% lighter than platinum, easing daily wear while maintaining ring integrity. Its fine grain structure supports crisp pavé and micro-prong work with reduced prong fatigue.

White gold advantages hinge on alloy engineering: nickel- or palladium-based systems elevate Vickers hardness, boost scratch resistance, and stabilize settings.

Rhodium plating enhances reflectance and surface durability, easily renewed during service. You’ll get reliable solderability, laser-weld compatibility, and predictable spring-back, which streamlines fabrication.

Choose palladium for weight-sensitive luxury; choose white gold for cost-efficient toughness.

Sterling Silver and Argentium: Enhanced Silver Choices for Everyday Wear

While platinum-group whites dominate luxury, sterling silver and its modern cousin Argentium deliver everyday practicality with credible performance.

You get predictable sterling silver properties: 92.5% silver alloyed primarily with copper, Vickers hardness typically 75–100 HV after work-hardening, excellent reflectivity, and high thermal conductivity for efficient soldering.

The trade-offs are tarnish formation via copper oxidation and moderate scratch resistance, so you’ll plan for occasional polishing and sensible wear.

Argentium advantages address those weak points. By replacing some copper with germanium, Argentium (935/960 fineness) forms a transparent germanium oxide that markedly reduces tarnish, improves firestain resistance, and enables low-temperature fusing.

It work-hardens well and age-hardens to higher hardness than standard sterling, enhancing durability in clasps, ear wires, and rings.

Choose Argentium for low-maintenance shine; pick sterling for maximum cost efficiency.

Frequently Asked Questions

Which Metals Are Safest for People With Nickel Allergies?

You should choose hypoallergenic metals like platinum, titanium, niobium, and 14k–18k palladium white gold; they’re nickel-free. Surgical-grade stainless steel (316L/316LVM) often works, but verify low nickel release. Avoid nickel-plated alloys to protect skin sensitivity.

How Do Metal Choices Impact Ring Resizing Options?

Metal choice dictates feasibility: gold and platinum resize predictably; titanium and stainless resist soldering; tungsten can’t resize. You’ll use ring resizing techniques like cutting and soldering, inserts, or remakes, guided by metal thickness considerations, work-hardening behavior, and heat tolerance.

What Metals Are Best for Engraved Detail Clarity?

Choose sterling silver, 14k–18k yellow gold, and platinum for crisp engraved detail. You’ll get superior clarity due to balanced metal hardness. Use engraving techniques like hand-engraving or laser for fine lines; avoid titanium or stainless—they resist clean cuts.

Which Metals Affect Airport or Metal Detector Screening?

You’ll trigger airport security metal detection with stainless steel, steel alloys, nickel, brass, bronze, and larger silver or gold pieces. Titanium and aluminum may alert scanners. Platinum rarely alarms. Remove bulky items; use plastic, fabric, or ceramic alternatives.

How Do Metals Perform in Saltwater or Chlorine Exposure?

Metals in saltwater or chlorine corrode variably: you’ll favor titanium and platinum for superior corrosion resistance, gold (high karat) moderate, stainless steel conditional, and silver poor. You’ll rinse promptly, dry thoroughly, and schedule maintenance requirements to prevent pitting and discoloration.

Conclusion

You’ve now seen how metals stack up on hardness, tensile strength, wear resistance, and maintenance. Choose tungsten carbide for maximum scratch resistance, titanium for strength-to-weight, and 316L steel for budget durability. Prefer dense luxury? Platinum or iridium alloys excel. Want color and workability? Opt for 10k–18k gold. Palladium and white gold balance lightness and wear. For everyday value, sterling and Argentium silver deliver. Match metal properties to lifestyle, finish preferences, resizing needs, and budget to get lasting performance.

コメントを書く

このサイトはhCaptchaによって保護されており、hCaptchaプライバシーポリシーおよび利用規約が適用されます。