What Are Ring Parts and How Do They Work?

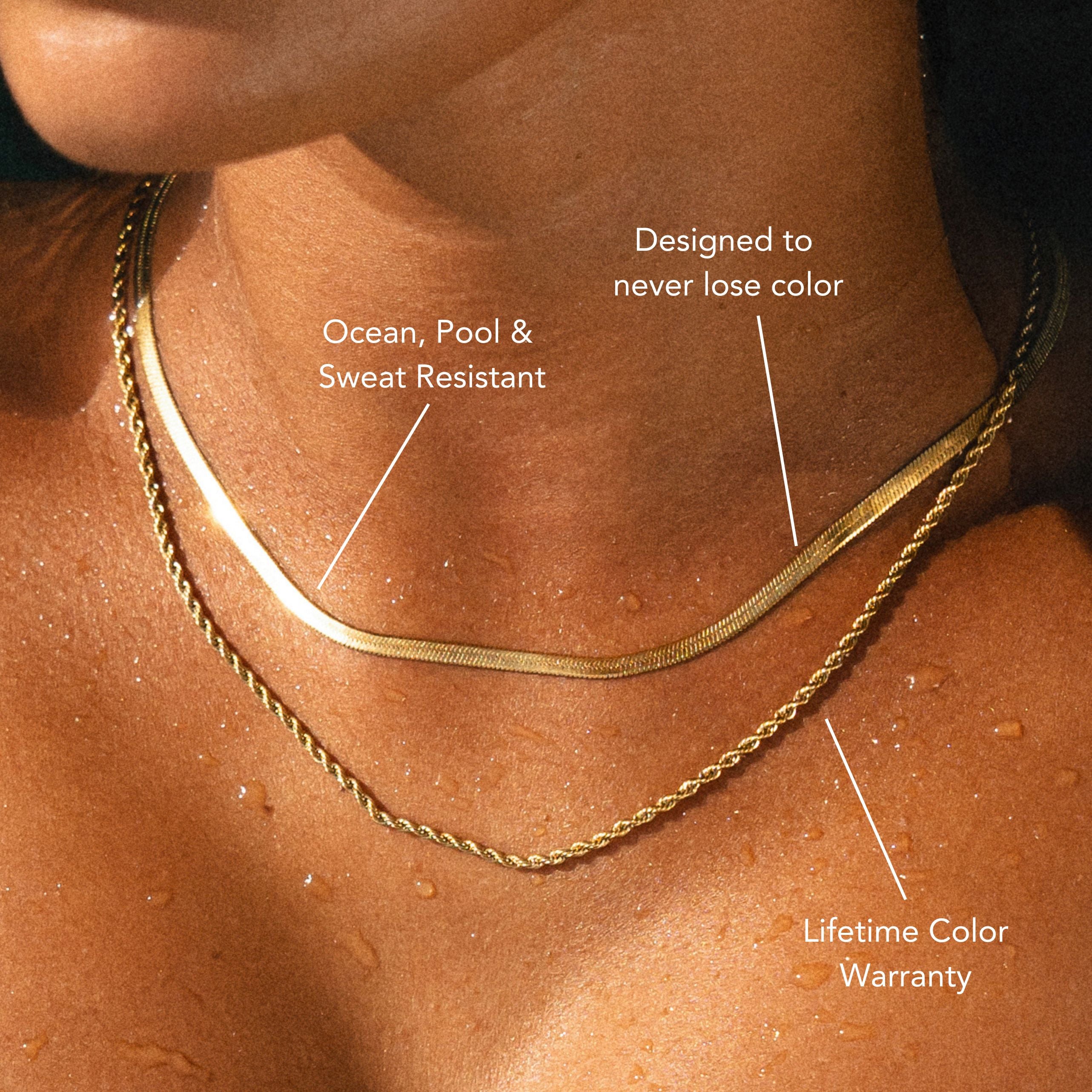

Ring parts are vital components that blend function and aesthetics, whether in jewelry or machinery. You've got the band for structure, the setting for showcasing gemstones, and prongs that enhance their brilliance. In industrial applications, they distribute tension and guarantee smooth motion. Materials like titanium and stainless steel offer durability, while unique designs, like tension rings, elevate style. Explore our collection of waterproof rings, which combine resilience with stunning designs. Proper installation and maintenance are essential for longevity and performance. Each part plays its role in delivering both beauty and functionality. Curious about how these innovations apply in different fields? Stick around to uncover even more fascinating details!

Definition of Ring Parts

When you think of a ring, you might picture a simple band of metal, but there's much more beneath the surface. The essence of a ring lies in its intricate design, where every curve, gemstone, and finish plays a pivotal role.

Ring parts aren't just components; they're a symphony of creativity and engineering. Imagine the band itself—its width and thickness, crafted to not only enhance aesthetics but also to provide durability.

Then there are the settings, which cradle your chosen gemstones, adding character and brilliance. Each setting is a result of meticulous manufacturing processes, ensuring that your precious stones are secure while also showcasing their natural beauty.

The shank, the part that encircles your finger, varies in style, from sleek and modern to ornate and vintage, reflecting personal taste and individuality.

Understanding ring parts enriches your appreciation for the artistry involved in jewelry creation. It's not merely about wearing a ring; it's about celebrating the craftsmanship that transforms raw materials into wearable art.

Types of Ring Parts

When it comes to ring parts, you'll find a fascinating array of components working together in harmony.

From the essential main ring elements that provide structure to the specialized features that enhance functionality, each part plays a vital role.

Understanding these types will empower you to appreciate the intricate mechanics behind every ring design.

Main Ring Components

Ever wondered how the intricate parts of a ring come together to create a seamless piece of jewelry? Understanding the main components can illuminate the art of ring design.

At the core, you'll find the band, which forms the ring's foundation, providing structure and stability. The setting is another essential element, holding gemstones securely in place while adding flair.

Next, consider the shank, a significant part of the band that determines the ring's overall fit and comfort. Whether it's a classic or contemporary style, assembly techniques play a notable role in how these components unite harmoniously.

Don't overlook the prongs, which cradle each stone, allowing light to dance through and enhance its brilliance.

Finally, the undergallery, often an unsung hero, adds elegance and supports the overall design.

When you grasp how these main ring components interact, you'll appreciate the craftsmanship that goes into each piece. The beauty of a ring lies not just in its appearance but in the thoughtful assembly of its parts, creating a stunning piece that tells a story of creativity and innovation.

Specialized Ring Elements

Specialized ring elements can transform a basic design into a true masterpiece. These components come in various forms, each offering unique functionalities that enhance both aesthetics and performance.

When you explore specialized configurations, you'll discover how they adapt to specific needs, whether for durability, flexibility, or style.

Consider the use of tension rings, which not only provide structural integrity but also create a sleek silhouette.

Or think about decorative elements like filigree or gemstones that add a touch of elegance and individuality to your piece. Each element allows you to play with innovative designs, pushing the boundaries of traditional ring craftsmanship.

You can also experiment with materials, combining metals like titanium with carbon fiber to achieve a modern, cutting-edge look.

Specialized elements like gaskets or seals can improve a ring's functionality in mechanical applications, proving that beauty and utility can coexist.

Functions of Ring Parts

When you think about ring parts, their functions are as essential as their forms. Each component plays a significant role in providing structural support, ensuring smooth motion, and maintaining perfect alignment, all while the material composition influences their overall performance.

Understanding these functions will give you a deeper appreciation of how these intricate pieces work together seamlessly.

Structural Support Mechanisms

Ring parts are essential for maintaining the structural integrity and functionality of various systems, whether in engineering, jewelry, or machinery. They serve vital roles in load distribution, ensuring that forces are evenly spread across a structure.

When you think about a bridge or a simple ring in a pendant, these components balance the weight and prevent localized stress that could lead to failure.

When you're conducting stress analysis, you'll find that ring parts excel in dispersing tension and compression. Their geometric shapes allow them to withstand significant loads without deforming. This is particularly important in machinery, where the slightest misalignment can cause catastrophic results.

In jewelry, the design of a ring also plays a role in aesthetic appeal while ensuring that it can endure everyday wear. The craftsmanship in these pieces reflects an understanding of how to balance beauty and strength.

Motion and Alignment Roles

Understanding how ring parts distribute loads naturally leads to their roles in motion and alignment. These components are pivotal in guaranteeing smooth kinematic behavior within mechanical systems. When you think about how machinery operates, the alignment of ring parts becomes critical. They act like guides, steering moving elements into precise positions, which directly affects the overall functionality of the system.

Imagine a well-oiled machine where every ring part is perfectly aligned. This alignment precision minimizes friction and wear, allowing for seamless shifts in motion. As parts rotate or slide, the rings guarantee that every movement is accurate, reducing the risk of misalignment that could lead to catastrophic failures.

In your designs, consider the implications of ring parts on kinematic behavior. When you optimize their placement and functionality, you enhance the efficiency and lifespan of the entire assembly.

Whether it's in a simple bearing or a complex gear system, the roles of motion and alignment that ring parts play are indispensable. Ultimately, understanding these functions will empower you to create more reliable and effective mechanical systems, guaranteeing that each component works harmoniously in the grand design.

Material Composition Impact

The choice of materials in ring components greatly influences their performance and durability in mechanical systems. When you select materials for your rings, think about how material durability will affect the entire system's longevity.

For example, metals like stainless steel or titanium offer impressive strength and resistance to wear, making them ideal for high-stress applications. You'll find these materials excel in maintaining integrity under pressure, ensuring your mechanisms run smoothly.

Corrosion resistance is another critical factor. If your ring parts are exposed to moisture or harsh chemicals, using materials like polymer composites or specialized coatings can protect against degradation.

By choosing corrosion-resistant materials, you not only enhance the lifespan of the components but also reduce maintenance costs over time.

In essence, balancing material durability and corrosion resistance can lead to innovative solutions that push the boundaries of what's possible in mechanical design.

Remember, the right material choice can transform a simple ring into a powerhouse of performance, optimizing your systems for efficiency and reliability.

Materials Used in Ring Parts

What makes a ring truly special often lies in the materials that compose its parts. You'll find that the choice of materials directly impacts the ring's durability, aesthetics, and functionality. Common materials include metals like steel, aluminum, and titanium, each boasting unique material properties.

For instance, titanium is lightweight yet incredibly strong, making it ideal for high-stress applications.

When it comes to manufacturing processes, the selection of materials plays an essential role. Techniques like precision casting or CNC machining require materials that can withstand heat and pressure, ensuring that the final product meets stringent quality standards.

You might also encounter polymers or composites in ring parts, particularly in applications where flexibility and shock absorption are critical.

Don't overlook the significance of surface finishes, either. Treatments such as anodizing or electroplating not only enhance appearance but also improve corrosion resistance, extending the lifespan of the ring parts.

Ultimately, the right combination of materials and manufacturing processes creates a harmonious balance, resulting in ring parts that perform exceptionally well while enchanting the eye. Your choice of materials can truly elevate the performance and appeal of ring components.

Applications of Ring Parts

Ring parts find their way into a myriad of applications, showcasing their versatility and significance across various industries. In automotive engineering, for instance, these components play an essential role in sealing and protecting engines from leaks, guaranteeing peak performance.

You'll find them in bearings, where they reduce friction and enhance efficiency, making vehicles smoother and more reliable.

In the aerospace sector, ring parts are integral to various systems, from fuel pumps to hydraulic systems, maintaining safety and functionality under extreme conditions.

The manufacturing and construction industries also benefit from these components; they're often used in machinery and equipment to provide structural integrity and support.

Ring part applications extend into the medical field as well. They're used in devices like syringes and surgical tools, where precision and reliability are paramount.

Even in electronics, you'll find these rings in connectors and circuit boards, vital for maintaining stable connections.

Ultimately, whether you're driving a car, flying in a plane, or using everyday devices, ring parts are silently working to guarantee everything runs smoothly, proving their invaluable role in modern technology and daily life.

Installation and Maintenance

When it comes to installing and maintaining ring parts, attention to detail is essential for guaranteeing ideal performance.

You'll want to start with the right installation techniques to secure a perfect fit. Always clean the surfaces where the rings will sit, as debris can lead to wear and tear. Use a proper torque specification when tightening any fasteners, and don't forget to apply lubrication where necessary. This guarantees that the rings operate smoothly and reduces friction over time.

Once installation is complete, establishing a reliable maintenance schedule is your next step.

Regularly inspect the ring parts for signs of wear or damage, and keep an eye on their performance under various conditions. Set reminders for periodic checks—monthly or quarterly, depending on usage—and document your findings. This proactive approach helps you catch potential issues early, allowing for timely interventions.

Troubleshooting Common Issues

Over time, you might encounter a few hiccups with your ring parts, but don't worry—troubleshooting these common issues can often be straightforward.

One frequent issue is ring part failures, which can stem from improper installation or wear over time. If you notice unusual sounds or decreased performance, inspect the parts for signs of damage or misalignment.

Next, consider making ring part adjustments. Sometimes, a simple tweak can resolve minor issues. Check for loose components that may need tightening, or explore the possibility of realigning the parts to guarantee they function smoothly together.

If you're dealing with leaks, examine the seals and gaskets closely. A worn-out seal might just need replacing, or it could be a simple case of needing a proper fit.

Lastly, don't hesitate to consult your manual or manufacturer's guidelines for specific troubleshooting tips tailored to your device.

Frequently Asked Questions

How Do Ring Parts Differ From Other Mechanical Components?

When you explore ring parts, you'll notice they emphasize unique ring design and specific material selection. Unlike other components, their function relies heavily on precise geometry and durability, showcasing innovative engineering tailored for specific applications.

Can Ring Parts Be Customized for Specific Applications?

Absolutely, you can create custom ring designs tailored for your needs. By selecting application-specific materials, you enhance performance and durability, ensuring your rings not only fit perfectly but also withstand unique environmental challenges.

What Are the Common Failures of Ring Parts?

Common failures of ring parts often stem from ring wear and installation issues. You might notice decreased performance if they're improperly fitted or subjected to excessive friction. Regular checks can help prevent these costly problems.

How Do Temperature Fluctuations Affect Ring Parts?

Temperature fluctuations can cause thermal expansion, leading to material fatigue in ring parts. You'll notice that repeated cycles of heating and cooling can weaken structures, increasing the risk of failure over time. Stay vigilant!

Are There Industry Standards for Ring Part Manufacturing?

Yes, there're industry standards for ring part manufacturing. You'll find tolerances specifications and material selections play vital roles. Adhering to these guarantees quality, performance, and longevity, making your products reliable in various applications.

Conclusion

In conclusion, ring parts are essential components that enhance the efficiency and longevity of various systems. By understanding their types, functions, and materials, you can make informed choices for your applications. Remember, proper installation and regular maintenance are key to avoiding common issues. So, as you explore the world of ring parts, you'll not only optimize performance but also open new possibilities for innovation in your projects. Embrace the journey and watch your ideas flourish!

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.