Is Stainless Steel Hypoallergenic? Facts You Need

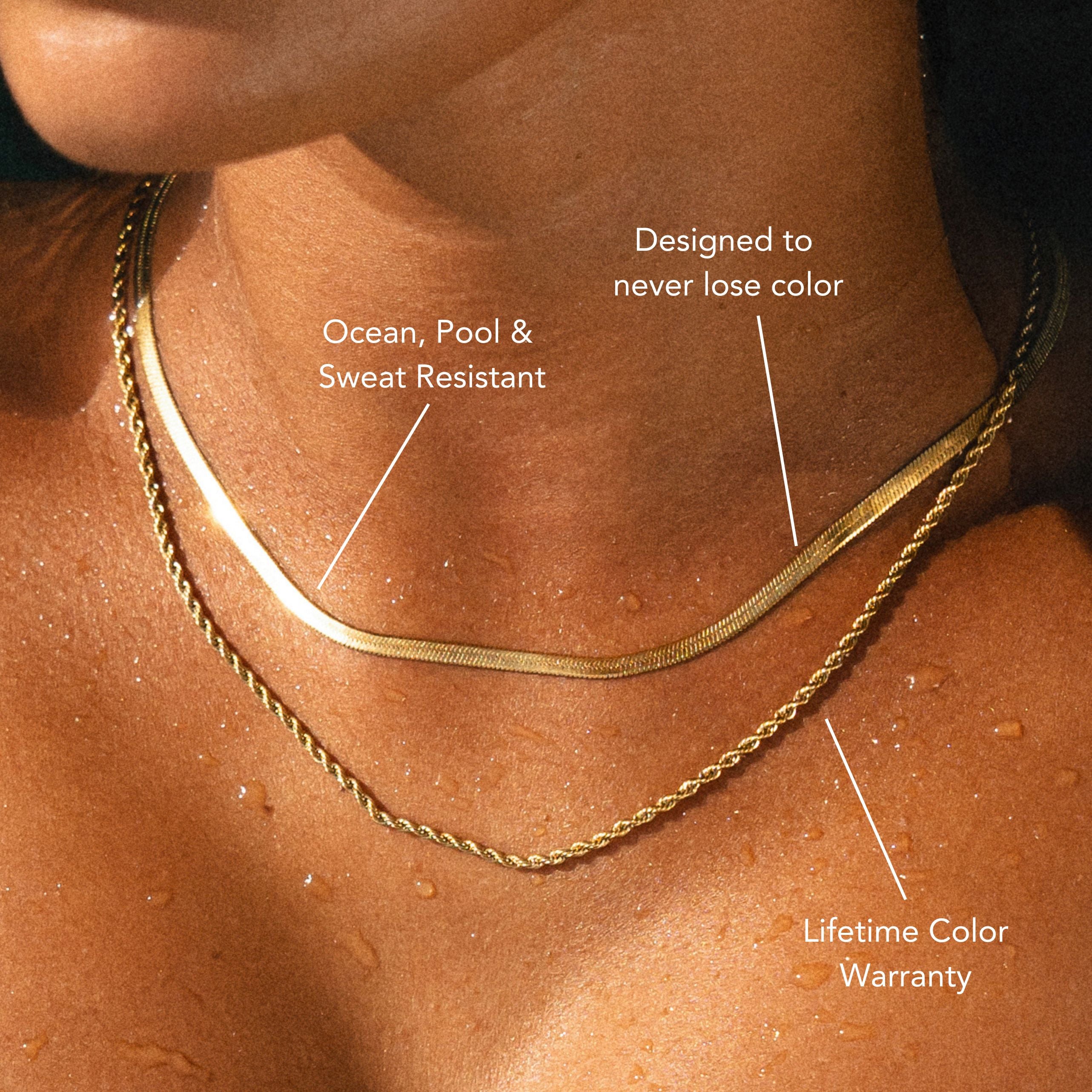

Is stainless steel hypoallergenic? Indeed, it can be, particularly when you opt for specific grades like 316L stainless steel, known for its lower nickel content. This alloy is composed of iron, chromium, and nickel, which together create a passivation layer that significantly reduces the likelihood of allergic reactions. The term hypoallergenic is used to describe materials that minimize the risk of allergic responses, an essential consideration for those with sensitive skin.

Additionally, the inherent corrosion resistance of stainless steel helps prevent the release of potential allergens. Nonetheless, it's important to note that prolonged exposure to certain grades with higher nickel content could still trigger contact dermatitis in some individuals. For comprehensive insights into managing allergies and choosing the appropriate stainless steel grade, explore our Hypoallergenic Jewelry collection for more details.

Understanding Stainless Steel

Stainless steel, an alloy primarily composed of iron, chromium, and nickel, is renowned for its corrosion resistance and durability. You might be aware that its exceptional properties make it a material of choice in various industries. In steel production, the alloying elements are meticulously combined and processed to achieve specific material properties.

When discussing stainless steel, it's important to take into account its microstructure, which contributes greatly to its performance. Austenitic stainless steels, for example, are known for their excellent toughness and formability. They owe these characteristics to their face-centered cubic crystal structure, which remains stable across a wide range of temperatures. This makes them ideal for applications requiring both strength and flexibility.

Another vital aspect is the passivation layer formed by chromium. This thin, inert film on the steel's surface protects it from oxidation and corrosion. In clinical settings, this property is particularly valuable, as it guarantees long-term reliability and hygiene. Ferritic and martensitic stainless steels also have unique material properties, such as magnetic behavior and higher strength, respectively.

Understanding these nuances in steel production and material properties helps you appreciate why stainless steel is indispensable in both everyday and specialized applications. It's not just durable but highly versatile.

Composition of Stainless Steel

You should understand that stainless steel is primarily composed of iron, chromium, nickel, and carbon. Each element contributes to its hypoallergenic properties and corrosion resistance.

Research indicates that the chromium content, typically above 10.5%, forms a passive layer that prevents oxidation and mitigates allergic reactions.

Alloying Elements Breakdown

When examining the composition of stainless steel, it's important to understand the role of its primary alloying elements: chromium, nickel, and molybdenum. Each of these elements greatly influences the alloy properties and metal strength of stainless steel.

Chromium, typically constituting 10-30% of the alloy, is paramount for enhancing hardness and tensile strength. Its presence forms a passive layer of chromium oxide on the surface, critical for durability.

Nickel, often added at levels between 8-10%, plays an important role in stabilizing the austenitic structure, which increases ductility and toughness. This means that stainless steel can endure high-stress environments without succumbing to fractures or deformation. Additionally, nickel contributes to the alloy's resistance to extreme temperatures, maintaining its structural integrity under various conditions.

Molybdenum, though usually present in smaller quantities (2-3%), greatly enhances the alloy's strength and hardness. It enhances the material's resistance to pitting and crevice corrosion, ensuring longevity and reliability.

The synergistic effect of these three elements—chromium, nickel, and molybdenum—creates a robust and versatile alloy, suitable for a wide array of applications, from medical implants to industrial machinery. Understanding these components is important for appreciating the wide-ranging benefits of stainless steel.

Corrosion Resistance Factors

Frequently, the exceptional corrosion resistance of stainless steel can be attributed to its meticulously balanced composition, with chromium playing a pivotal role in forming a passivating oxide layer that shields the underlying metal. Typically, stainless steel contains at least 10.5% chromium, which is essential for this protective barrier. The addition of other elements such as nickel, molybdenum, and nitrogen further enhances its resistance to various corrosive environments.

You should be aware that the types available in stainless steel, such as austenitic, ferritic, martensitic, and duplex, differ in their specific compositions and properties. Austenitic stainless steels, for instance, are known for their superior corrosion resistance due to higher nickel and chromium content. Conversely, ferritic and martensitic types have varied chromium levels and lower nickel content, affecting their corrosion resistance and mechanical properties.

Processing methods critically influence the corrosion resistance of stainless steel. Techniques like cold working, annealing, and surface treatments can alter the material's microstructure, enhancing its protective capabilities. Cold working increases strength but may reduce corrosion resistance unless followed by proper annealing.

Surface treatments, such as passivation, can restore or augment the protective oxide layer, ensuring long-term durability. By understanding these factors, you can select the best stainless steel type and processing method for your specific application.

What Hypoallergenic Means

Hypoallergenic refers to substances or materials that are less likely to cause allergic reactions. According to the medical definition, a hypoallergenic material minimizes the risk of triggering an immune response.

When your body encounters an allergen, your immune system may mistakenly identify it as harmful, leading to symptoms like itching, redness, or even more severe reactions.

Understanding what hypoallergenic means is important in selecting materials for personal use. Research indicates that hypoallergenic products are designed to minimize the likelihood of causing an allergic reaction. This is particularly important for individuals with sensitive skin or a history of allergic reactions. Clinical studies often focus on the biocompatibility of materials, evaluating their potential to trigger adverse immune responses.

You might wonder how certain materials achieve their hypoallergenic status. It's not just about what they include, but also what they exclude. Hypoallergenic materials typically avoid common allergens and irritants, which reduces the risk of an immune response.

Common Allergens in Metals

You should be aware that nickel and chromium are common allergens in metals, often triggering contact dermatitis. Research indicates nickel is the most prevalent cause of metal-induced skin reactions.

Chromium, although less common, can still lead to significant sensitivity concerns, especially in individuals with pre-existing conditions.

Nickel and Skin Reactions

Nickel, a prevalent component in many metal alloys, often triggers contact dermatitis in susceptible individuals. When you experience nickel exposure, your immune system can perceive nickel ions as harmful, leading to an allergic reaction. This response manifests as skin irritation, characterized by redness, itching, and sometimes blistering. Research indicates that even minimal contact with nickel can provoke symptoms in individuals with nickel allergy.

Understanding the pathophysiology of nickel allergy is essential. It involves a type IV hypersensitivity reaction, where T-cells recognize nickel ions and release cytokines, causing inflammation. Epidemiological studies show that up to 10-20% of the population may be sensitive to nickel, making it a common allergen. The European Union has even implemented regulations to limit nickel release in consumer products to mitigate this issue.

In clinical settings, patch testing is the gold standard for diagnosing nickel allergy. If you suspect a nickel allergy, consult a dermatologist to confirm the diagnosis. Avoiding nickel-containing items, such as certain jewelry and watchbands, can significantly reduce the risk of skin reactions. Opt for alternatives like surgical-grade stainless steel, which has lower nickel content and is less likely to cause adverse effects.

Chromium Sensitivity Concerns

Chromium, another common allergen in metals, can cause contact dermatitis in individuals with sensitivity, leading to skin reactions similar to those triggered by nickel. If you experience redness, itching, or blistering upon contact with stainless steel or other chromium-containing items, you might be experiencing chromium sensitivity.

This condition manifests when your immune system reacts adversely to chromium ions, often found in various metal alloys.

One way to identify chromium sensitivity is through allergy testing, specifically patch testing. This clinical procedure involves applying small amounts of chromium compounds to your skin and monitoring for reactions over several days. Positive results indicate sensitivity and necessitate avoiding chromium-laden materials.

Beyond dermatitis, you should also be aware of the broader implications of chronic exposure to chromium. While rare, chromium toxicity can occur, leading to more severe health issues such as respiratory problems and systemic toxicity.

It's important to differentiate between the two primary forms of chromium: trivalent chromium (Cr III), which is less likely to cause reactions, and hexavalent chromium (Cr VI), a known irritant and carcinogen.

Stainless Steel and Allergies

When considering the relationship between stainless steel and allergies, it's vital to understand the alloy's composition and its potential to release allergenic metals. Stainless steel is primarily composed of iron, chromium, and nickel, with varying percentages depending on the specific grade.

For instance, 304 stainless steel contains approximately 18% chromium and 8% nickel, both of which can induce allergic reactions in susceptible individuals.

You might experience skin irritation if you have a sensitivity to nickel or chromium. Research indicates that prolonged exposure to these metals can lead to contact dermatitis, a condition characterized by redness, itching, and inflammation.

Effective allergy management involves identifying the specific allergens triggering your symptoms. In the context of stainless steel, hypoallergenic grades such as 316L, which has a lower nickel content, are often recommended for individuals with metal sensitivities.

Moreover, it's important to note that the risk of allergic reactions can vary based on the stainless steel's quality and how it's processed. High-quality stainless steel undergoes passivation, a process that forms a protective oxide layer, reducing the release of allergenic metals.

Understanding these factors helps you make informed decisions about using stainless steel in everyday items, from jewelry to medical implants.

Tips for Sensitive Skin

For managing sensitive skin, it's crucial to select materials that minimize allergenic potential and maintain proper skincare routines. Opt for skin-friendly metals like stainless steel, known for its hypoallergenic properties.

Make sure your jewelry care regimen includes regular cleaning to remove potential irritants such as sweat, dirt, and cosmetics. This practice helps mitigate contact dermatitis and other allergic reactions.

When choosing jewelry, prioritize pieces labeled as hypoallergenic or nickel-free, as nickel is a common allergen. Stainless steel, particularly surgical grade, offers a durable and skin-friendly option. Always examine product specifications and customer reviews for insights about the metal's composition and potential allergenic effects.

Incorporate a consistent skincare routine to fortify your skin's barrier function. Use gentle, fragrance-free cleansers and moisturizers designed for sensitive skin. After removing jewelry, cleanse the skin area to eliminate any residues that might cause irritation.

Lastly, consult with a dermatologist if you experience persistent skin issues. They can provide personalized recommendations tailored to your skin type and sensitivities. By combining mindful jewelry care with a robust skincare regimen, you can significantly reduce the risk of allergic reactions and maintain healthier skin.

Frequently Asked Questions

Can Stainless Steel Cause Skin Discoloration?

Yes, stainless steel can cause skin discoloration if it contains nickel. The nickel content may trigger allergic reactions, leading to redness, itching, and discoloration. Always check for nickel-free options to avoid these issues.

Is Surgical Stainless Steel Different From Regular Stainless Steel?

Yes, surgical stainless steel differs from regular stainless steel due to composition differences. Surgical stainless steel has lower nickel content, reducing allergic reactions, whereas regular stainless steel contains more nickel, increasing the potential for skin irritation.

How Do I Clean Stainless Steel Jewelry to Avoid Skin Reactions?

To clean stainless steel jewelry and avoid skin reactions, use mild cleaning solutions like diluted dish soap. Apply with gentle scrubbing using a soft toothbrush. Rinse thoroughly and dry to prevent irritation and maintain hypoallergenic properties.

Are There Any Coatings That Make Stainless Steel More Hypoallergenic?

Yes, there are protective coatings that enhance stainless steel's hypoallergenic properties. PVD (Physical Vapor Deposition) and rhodium plating are commonly used to create a barrier, reducing the release of nickel and other potential allergens.

Can Children Wear Stainless Steel Jewelry Safely?

Yes, children can wear stainless steel jewelry safely, but you should check for nickel content. Lower nickel levels reduce the risk of skin irritation. Research shows that surgical-grade stainless steel is often the safest option.

Conclusion

To sum up, if you're concerned about metal allergies, stainless steel is generally a safe choice due to its low allergenicity. Its composition minimizes the presence of common allergens like nickel and chromium.

However, always check for specific grades known for hypoallergenic properties. For those with sensitive skin, opting for high-quality surgical stainless steel can greatly reduce the risk of allergic reactions.

Research supports stainless steel as a reliable option for minimizing metal-induced dermatological issues.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.