PVD Jewelry Durability: How Long Does It Last?

Understanding PVD Coating

PVD coating, or Physical Vapor Deposition, involves the process of vaporizing a solid material in a vacuum and depositing it onto the jewelry's surface to enhance durability and aesthetic appeal. This PVD application starts by placing the jewelry inside a specialized vacuum chamber. The coating material, typically a high-quality metal like titanium or zirconium, is then vaporized using a high-energy source such as an electron beam or sputtering process.

During the coating process, the vaporized atoms condense onto the jewelry, forming a thin, yet incredibly hard, layer. This layer bonds at a molecular level, creating a finish that resists wear, tarnish, and corrosion. The result is a protective and decorative layer that can prolong the life of your jewelry to a great extent.

One key advantage of the PVD application is its versatility. You can achieve various colors and finishes depending on the material and process parameters. Additionally, PVD coatings are highly consistent, ensuring uniform coverage and excellent adhesion.

Understanding the intricacies of the coating process allows you to appreciate the enhanced performance and longevity PVD coatings bring to jewelry, making it a superior choice for high-end applications.

Comparing PVD to Other Finishes

When assessing the durability and performance of jewelry finishes, it's crucial to consider how PVD coatings compare to traditional methods like electroplating and anodizing.

PVD, or Physical Vapor Deposition, involves a unique coating process carried out in a vacuum environment, where metal vapor condenses onto the jewelry surface. This technique enables a highly uniform, hard, and durable coating.

In contrast, electroplating relies on an electrochemical process to deposit a metal layer onto the jewelry. While electroplating can achieve a visually appealing finish, it often lacks the durability of PVD because the bond between the coating and the base material is generally weaker. Electroplated finishes can wear off more quickly, especially with frequent use.

Anodizing, typically used for aluminum jewelry, involves an electrochemical process that increases the thickness of the natural oxide layer on the metal's surface. Though anodizing offers decent wear resistance and corrosion protection, it doesn't match the hardness and adhesive strength of PVD coatings.

Factors Affecting PVD Durability

To truly understand why PVD coatings excel in durability, you must consider various factors such as substrate material, coating thickness, deposition parameters, and post-treatment processes.

First, the substrate material plays a vital role in material compatibility. For instance, stainless steel and titanium are highly compatible substrates that enhance the adhesion and longevity of the PVD coating.

Next, coating thickness is a significant determinant. A thicker PVD layer generally offers better wear resistance, although excessive thickness can lead to brittleness. Striking the right balance is essential.

Deposition parameters like temperature, pressure, and deposition rate also impact the quality of the coating. Optimal settings ensure a uniform and dense layer, which translates to enhanced durability.

Application techniques, such as sputtering and arc evaporation, determine how well the coating bonds to the substrate. Sputtering often results in smoother finishes, whereas arc evaporation can produce denser coatings.

Post-treatment processes, including annealing and polishing, refine the coating, improving its wear resistance and aesthetic appeal.

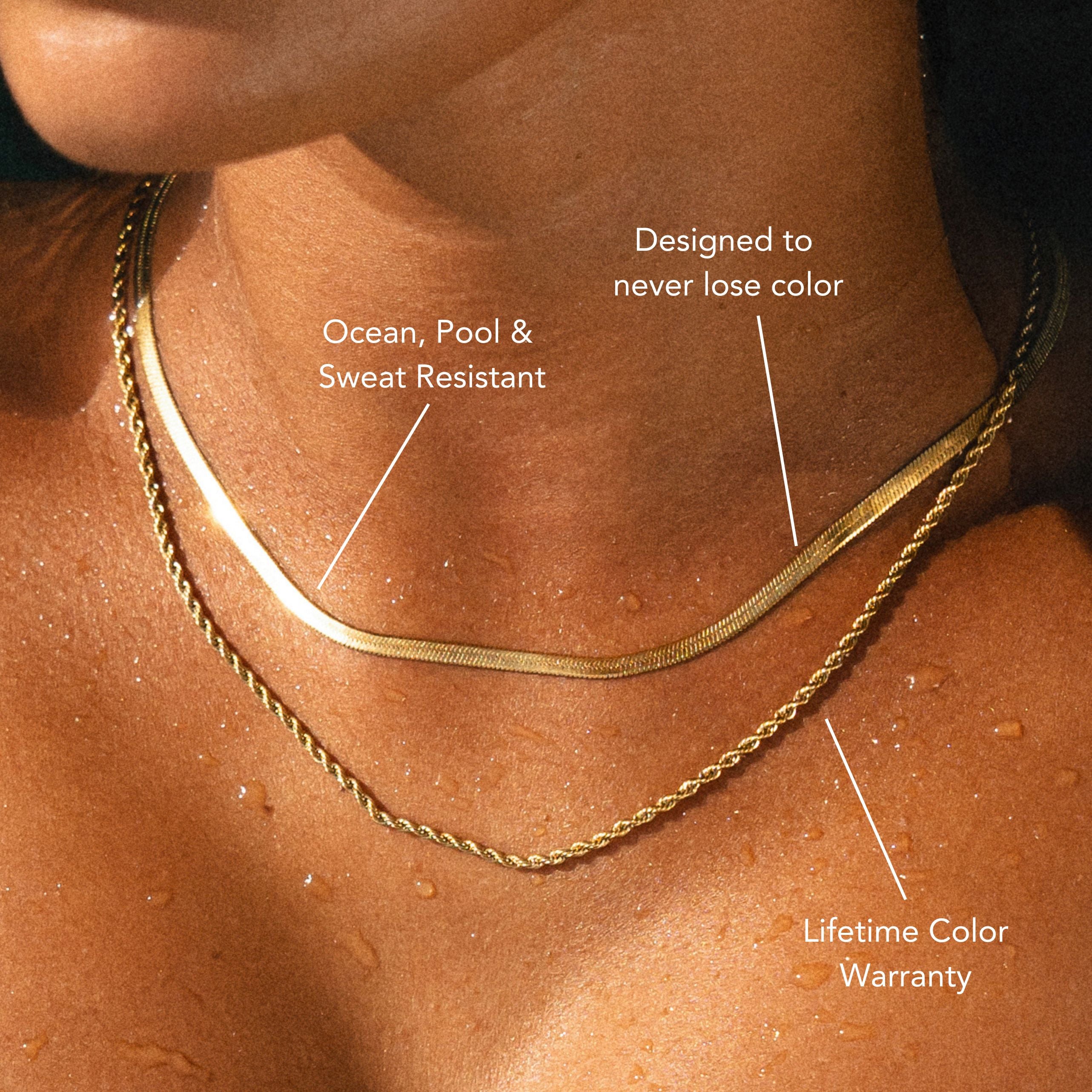

Maintenance Tips for PVD Jewelry

Maintaining the lifespan of your PVD-coated jewelry requires meticulous care and adherence to specific maintenance protocols. Start with a consistent cleaning routine. Use a mild soap solution and a soft cloth to gently wipe your jewelry. Avoid abrasive cleaners or brushes, as they can damage the PVD coating. Rinse thoroughly with lukewarm water and pat dry using a lint-free cloth. This guarantees that no residues are left, which could potentially dull the finish.

Next, consider your storage methods. Store each piece separately in a soft pouch or lined jewelry box to prevent scratches and minimize exposure to air and moisture. Humidity accelerates the tarnishing process, so incorporating silica gel packets can help control moisture levels.

Additionally, avoid exposing your PVD jewelry to harsh chemicals found in household cleaners, perfumes, and chlorinated water, as these can erode the coating. When engaging in activities like swimming, exercising, or cleaning, it's best to remove your jewelry to preserve its integrity.

Real-World Longevity of PVD

The real-world longevity of PVD jewelry hinges on several factors including the thickness of the coating, the quality of the base material, and the wearer's lifestyle.

A thicker PVD coating generally enhances durability, as the vacuum process used during PVD deposition guarantees a uniform and robust layer. This process involves ion bombardment, which enhances adhesion between the PVD layer and the base material, reducing the likelihood of peeling or chipping.

The quality of the base material also plays a critical role. High-quality stainless steel or titanium bases offer better longevity due to their inherent resistance to corrosion and wear. On the other hand, inferior base materials may degrade faster, impacting the overall lifespan of the PVD coating.

Your lifestyle can have a significant impact on how long your PVD jewelry lasts. Activities that expose the jewelry to harsh chemicals, abrasive surfaces, or frequent impacts can accelerate wear and tear. However, with proper care and mindful use, PVD jewelry can maintain its pristine appearance for years.

Frequently Asked Questions

Can PVD Coating Be Applied to All Types of Jewelry?

You can apply PVD coating to most types of jewelry, but application methods and surface preparation are vital. Properly prepared surfaces guarantee excellent adhesion and longevity, while different methods cater to various materials and design complexities.

Is PVD Jewelry Hypoallergenic and Safe for Sensitive Skin?

Yes, PVD jewelry is generally hypoallergenic and safe for sensitive skin. The process minimizes allergenic reactions due to its material compatibility, creating a barrier that prevents direct contact with potentially irritating base metals.

What Are the Environmental Impacts of PVD Coating Processes?

You should know that the PVD coating process involves significant energy consumption, but waste management is efficient. The process produces minimal hazardous waste, making it environmentally friendlier compared to other coating methods.

Are There Color Limitations for Pvd-Coated Jewelry?

You won't face color limitations with PVD-coated jewelry. The process offers extensive color variety and design flexibility. Utilizing advanced industry techniques, PVD guarantees diverse, vibrant hues that maintain their appearance, enhancing your design possibilities greatly.

How Does PVD Coating Affect the Weight of Jewelry Pieces?

PVD coating's effect on jewelry weight is minimal due to its ultra-thin layer. Weight distribution remains uniform, and the coating thickness, usually nanometers, doesn't notably alter the piece's overall weight, preserving its original feel and balance.

Conclusion

By understanding PVD coating, you'll appreciate its superior durability compared to other finishes. Factors like material quality and environmental exposure impact its longevity.

Proper maintenance, such as avoiding harsh chemicals and regular cleaning, guarantees your PVD jewelry remains pristine. Real-world data confirms that PVD-coated pieces often last several years, maintaining their appearance with minimal wear.

With diligent care, your PVD jewelry will provide long-lasting elegance and resilience, making it a worthwhile investment.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.