What is PVD Jewelry? Explained Simply

What is PVD jewelry? It's a type of jewelry that utilizes Physical Vapor Deposition to apply a thin, durable coating in a high-vacuum environment. This advanced method involves vaporizing metals like titanium or gold and condensing them onto the jewelry. The use of a vacuum chamber ensures that the coating is pure and adheres well to the base material. PVD coatings are known for their enhanced scratch, fade, and tarnish resistance, providing a smooth and uniform finish with a variety of color options. Offering superior durability and longevity compared to traditional electroplating, PVD bonds at a molecular level with the base material. To maintain its luster and durability, proper storage and cleaning of PVD jewelry are essential. Interested in exploring products featuring this advanced technology? Check out our Hypoallergenic Jewelry collection.

Understanding PVD Technology

Understanding PVD technology starts with recognizing that Physical Vapor Deposition (PVD) is a sophisticated method used to coat jewelry with thin layers of material to enhance durability and aesthetic appeal.

In PVD, you're dealing with a process that involves creating a vital high-vacuum environment. This vacuum chamber is essential because it guarantees that the coating materials can be vaporized and deposited onto the jewelry surface without contamination.

The coating materials used in PVD are typically metals like titanium, zirconium, or gold. These materials are chosen for their superior hardness and resistance to tarnish. When placed inside the vacuum chamber, these materials are heated until they vaporize. This vapor then condenses onto the jewelry in a thin, uniform layer, creating a coating that's both durable and aesthetically pleasing.

You might wonder why a vacuum chamber is necessary. It's because the absence of air prevents unwanted reactions with other gases, ensuring the purity and adhesion of the coating. Understanding this process gives you insight into why PVD-coated jewelry stands out regarding both longevity and visual appeal.

The PVD Jewelry Process

To grasp the intricacies of the PVD jewelry process, you must start with the meticulous preparation of the jewelry surface, making sure it's clean and free of any contaminants. This initial step is vital as any residue or debris can compromise the PVD application.

The jewelry is then placed in a vacuum chamber where the actual PVD coating process begins. Inside the chamber, a target material, often a metal like titanium or gold, is vaporized through a method known as sputtering or arc evaporation. This vaporized material condenses onto the jewelry, forming a thin, yet highly durable coating.

The process uses various gases, such as nitrogen or argon, which react with the vaporized material to create different types of coatings, enhancing both appearance and durability. The PVD application is conducted under controlled conditions to ensure a uniform and consistent layer. This guarantees that the coating adheres well, greatly boosting its durability.

The entire process is monitored closely to maintain precision, ensuring the jewelry achieves the desired aesthetic and protective qualities. With the PVD method, you get a finish that's not only visually appealing but also resistant to wear and corrosion.

Benefits of PVD Jewelry

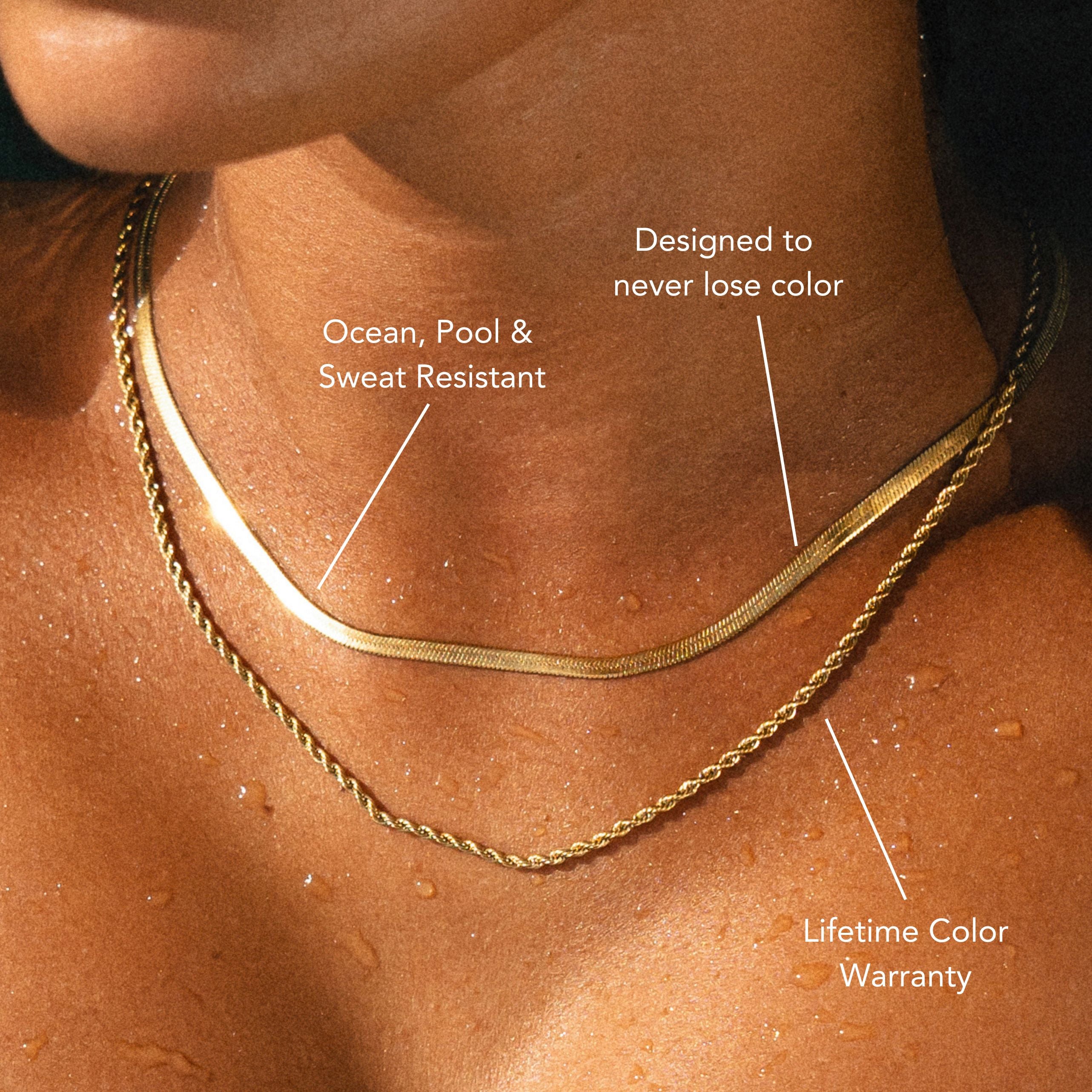

PVD jewelry offers unparalleled benefits, combining exceptional durability with a visually stunning finish that's resistant to wear and corrosion. The durability benefits of PVD (Physical Vapor Deposition) are one of the key reasons why it's a preferred choice for high-quality jewelry.

This advanced coating process creates a hard, thin film on the jewelry surface, greatly enhancing its resistance to scratches, fading, and tarnishing. You'll find that PVD-coated pieces maintain their original luster and color much longer than those coated with traditional methods.

In terms of aesthetic advantages, PVD jewelry is truly remarkable. The process allows for a wide range of color options, from classic gold and silver to vibrant hues like rose gold and black. These colors aren't just skin-deep but are integrated into the metal, ensuring they remain vivid and consistent over time.

Additionally, the finish is smooth and uniform, providing a high-end look that elevates the overall appearance of the piece.

Comparing PVD to Other Coatings

When comparing PVD jewelry to other coatings, it becomes evident that PVD offers superior durability and longevity, setting a higher standard in the jewelry industry. PVD, or Physical Vapor Deposition, creates a thin yet robust layer that bonds at a molecular level with the base material. This results in a coating that's notably harder and more resistant to wear compared to alternative coatings like electroplating or traditional plating methods.

Coating durability is an important factor when evaluating the quality of jewelry. PVD coatings are known for their exceptional scratch and corrosion resistance. This is due to the advanced vacuum chamber process that ensures an even and consistent application, leaving no room for weak spots. In contrast, electroplated jewelry often suffers from uneven thickness and can wear off more quickly, exposing the base metal and leading to tarnish.

Alternative coatings, such as anodizing or enameling, offer various aesthetic benefits but fall short in terms of durability. Anodized coatings can fade with time, and enamel can chip under stress. PVD, however, maintains its luster and integrity, providing a long-lasting, high-quality finish that outperforms these other methods.

Caring for PVD Jewelry

Proper care is vital to maintain the durability and brilliance of your PVD-coated jewelry, guaranteeing it continues to look as impeccable as the day you bought it. To keep your pieces in top condition, start with proper cleaning techniques. Use a soft, lint-free cloth to gently wipe away any dirt or oils. For a deeper clean, mix mild soap with lukewarm water, and use a soft-bristled toothbrush to gently scrub the jewelry, avoiding harsh chemicals that could damage the coating.

When it comes to storage solutions, always keep your PVD jewelry separate from other pieces to prevent scratches. Use a fabric-lined jewelry box or individual pouches to minimize contact with other items. It's also advisable to store your jewelry in a cool, dry place, away from direct sunlight and moisture, as these elements can degrade the coating over time.

Additionally, avoid wearing PVD-coated jewelry during activities that expose it to harsh conditions, such as swimming in chlorinated pools or engaging in heavy manual labor.

Frequently Asked Questions

Is PVD Jewelry Hypoallergenic?

Yes, PVD jewelry is generally hypoallergenic. It minimizes allergic reactions and suits skin sensitivity. The coating process creates a barrier, reducing nickel exposure, which is a common irritant, making it a safer choice for sensitive skin.

Can PVD Jewelry Be Resized?

When considering the resizing process for PVD jewelry, you'll find potential limitations. The PVD coating might get damaged or compromised during resizing, making it essential to consult a professional jeweler experienced with PVD-coated items.

What Metals Are Commonly Used in PVD Jewelry?

You're asking about the metals in PVD jewelry. Common alloys include stainless steel and titanium as base materials. These metals provide durability and corrosion resistance, making them ideal for the PVD process and long-lasting jewelry.

Is PVD Coating Environmentally Friendly?

Yes, PVD coating is environmentally friendly. You'll benefit from its reduced waste production and energy efficiency. Unlike traditional plating methods, PVD uses less harmful chemicals and operates at lower temperatures, making it a greener choice.

How Long Does PVD Jewelry Last?

PVD jewelry's durability is impressive, often lasting years without tarnishing. When comparing durability, PVD's wear resistance surpasses traditional plating methods, offering superior protection against scratches and fading, ensuring your pieces maintain their luster over time.

Conclusion

To conclude, PVD jewelry offers a superior, durable finish that outperforms traditional coating methods. By understanding PVD technology and its process, you'll appreciate its advantages, such as enhanced wear resistance and a longer lifespan.

Compared to other coatings, PVD stands out for its resilience and eco-friendly nature. To maintain your PVD jewelry's pristine condition, follow simple care guidelines. Embrace the benefits of PVD jewelry and enjoy its lasting elegance and durability.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.