What Metal Is Waterproof?

Stainless steel stands out as a waterproof metal because of its corrosion resistance and protective chromium layer. This metal can endure tough environments, making it a popular choice for various applications, including jewelry. If you're keen to discover more about other waterproof metals, the properties of aluminum, titanium, copper, and zinc could intrigue you further. To explore a collection that harnesses these durable materials in stylish ways, check out our Waterproof Jewelry collection, where each piece is crafted to withstand the elements while enhancing your everyday style.

Stainless Steel: A Waterproof Wonder

Stainless steel, renowned for its exceptional corrosion resistance and durability, stands out as a waterproof wonder in various industrial applications. When it comes to rust prevention, stainless steel excels due to its composition, primarily featuring chromium. This alloy element forms a protective layer of chromium oxide on the surface of the steel, preventing rust from developing and enhancing its longevity.

The durability of stainless steel is unmatched, making it a reliable choice for environments where water exposure is prevalent. Its ability to withstand harsh conditions without succumbing to corrosion makes it a top contender for applications requiring water-resistant properties. Whether used in marine environments, food processing facilities, or architectural structures, stainless steel's durability provides a long-lasting, waterproof solution.

Its versatility and strength further contribute to its reputation as a go-to material for industries where maintaining the integrity of structures in wet conditions is paramount.

Aluminum: Lightweight and Water-Resistant

Aluminum, known for its lightweight nature and water-resistant properties, is a versatile material widely utilized in various industries for its durability and corrosion resistance. When it comes to waterproofing, aluminum offers significant advantages. Its lightweight composition makes it easy to work with while still providing excellent strength. The water-resistant properties of aluminum stem from its natural oxide layer, which forms upon exposure to air, creating a protective barrier against moisture. This oxide layer also contributes to aluminum's corrosion resistance, ensuring longevity in challenging environments.

The benefits of using aluminum for waterproofing applications are vast. Its durability factor is a key highlight, as aluminum can withstand harsh weather conditions without deteriorating. The material's resistance to corrosion further enhances its suitability for outdoor use, making it a popular choice for structures exposed to the elements. Additionally, aluminum's malleability allows for intricate designs to be easily achieved, catering to a wide range of aesthetic preferences while maintaining its water-resistant properties.

Titanium: Corrosion-Resistant Metal

Titanium, renowned for its exceptional resistance to corrosion, is a highly sought-after metal in various industries for its robust properties when exposed to challenging environments. One of the key factors contributing to titanium's popularity is its remarkable strength. Titanium strength is renowned for its high tensile strength-to-density ratio, making it incredibly strong while remaining lightweight. This strength is vital in applications where durability and reliability are paramount.

Furthermore, titanium's corrosion resistance is unparalleled. When exposed to moisture, titanium forms a thin oxide layer on its surface that protects it from further corrosion. This oxide layer is stable and self-healing, ensuring long-term protection against harsh environmental conditions. This corrosion resistance makes titanium an ideal choice for equipment and structures that are constantly exposed to water or corrosive substances.

Copper: Weathering the Elements

Facing various environmental challenges, copper demonstrates remarkable resilience in enduring the elements due to its inherent properties and unique characteristics.

One of the most notable features of copper is its ability to develop a protective layer called copper patina when exposed to the elements over time. This patina acts as a natural barrier, enhancing the metal's resistance to corrosion and weathering.

Copper's durability has been extensively studied through rigorous durability tests, where it consistently outperforms many other metals in harsh environments. These tests assess factors such as the metal's ability to withstand extreme temperatures, moisture, and atmospheric conditions without compromising its structural integrity.

The results highlight copper's exceptional durability and suitability for outdoor applications where exposure to the elements is inevitable. By forming a protective patina and excelling in durability tests, copper proves to be a reliable choice for various construction, roofing, and outdoor decorative applications, showcasing its capability to weather the elements effectively.

Zinc: A Protective Barrier

Zinc forms a robust protective barrier against corrosion and weathering, making it a valuable material for various applications exposed to harsh environmental conditions. When used as a coating on other metals, zinc acts as a sacrificial anode, corroding preferentially to protect the underlying substrate. This mechanism is important for rust prevention in structures like bridges, pipelines, and offshore platforms. The zinc layer creates a physical barrier that shields the metal surface from moisture, chemicals, and abrasion, enhancing the material's long-term durability.

In addition to its corrosion-resistant properties, zinc offers excellent adhesion to different substrates, ensuring a lasting protective shield. This adhesion is essential for maintaining the integrity of the coating over time, even in challenging environments. The combination of zinc's sacrificial protection and strong adhesion makes it a preferred choice for applications requiring robust rust prevention and long-lasting performance. Whether used in galvanized steel products, automotive components, or architectural elements, zinc's protective barrier plays an important role in enhancing the durability and longevity of metal structures.

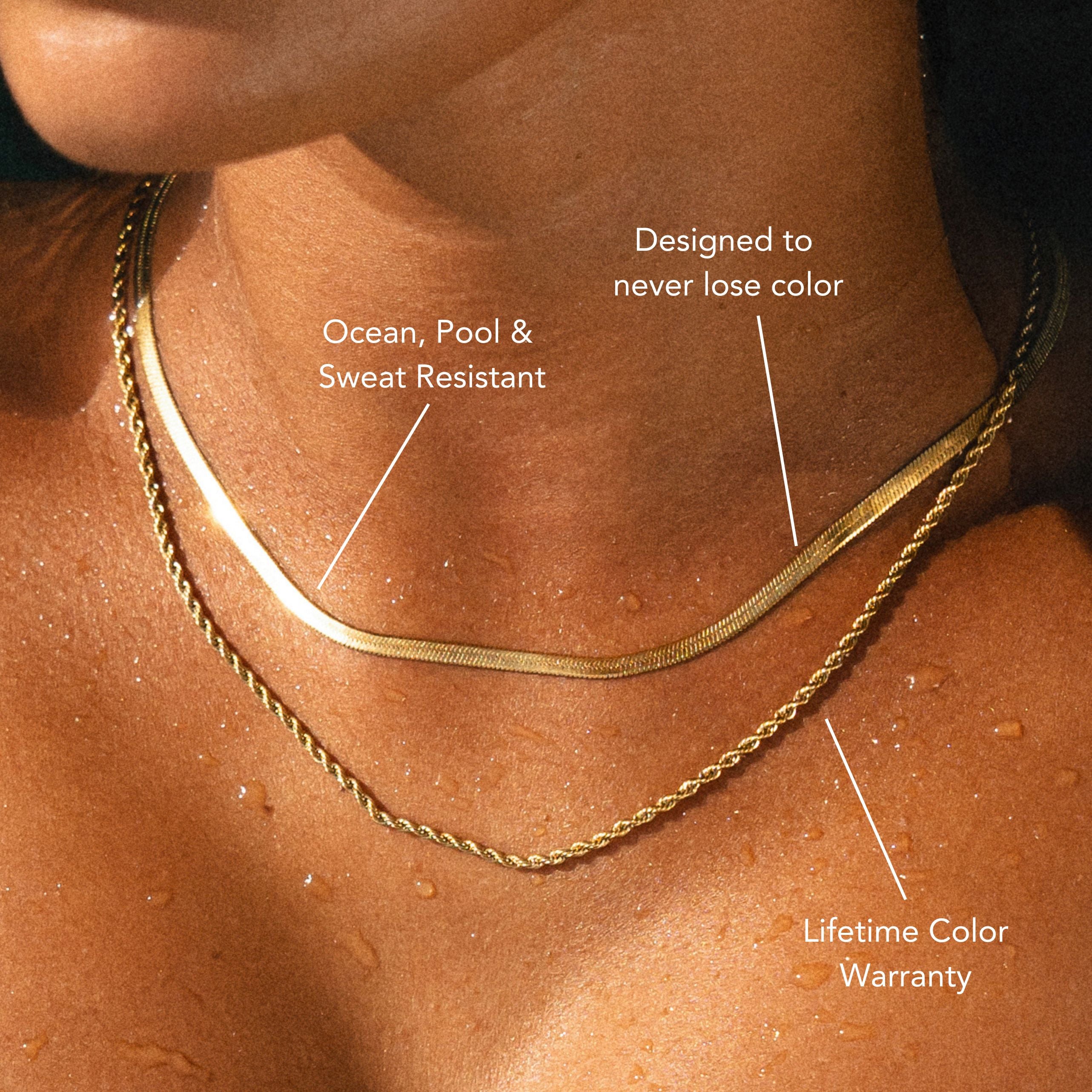

Atolea Jewelry’s Waterproof Collection

At Atolea Jewelry, we specialize in crafting exquisite waterproof jewelry that defies the limits of everyday wear. From showers and pool dives to sweaty gym sessions and rainy days, our jewelry stands the test of time and elements. Here’s what makes our collection special:

- Lifetime Color Warranty: Each piece of Atolea Jewelry comes with a lifetime color warranty, ensuring your jewelry maintains its luster and finish no matter how often it comes into contact with water.

- High-Quality Materials: We use the best waterproof metals, including stainless steel and platinum, to ensure durability and shine that lasts.

- Designed for Daily Wear: Our jewelry is made to be a constant in your life, capable of going wherever you go without the need to remove it.

Embrace the Atolea Lifestyle

Join over 300,000 happy customers who are part of the ATOLEA family. Experience the confidence and freedom that comes with wearing jewelry that you never have to worry about. Whether you are showering, heading to the gym, or getting caught in the rain, Atolea Jewelry’s pieces are crafted to never fade, promising both style and durability.

Frequently Asked Questions

Can I Use Stainless Steel in Saltwater Environments?

You can use stainless steel in saltwater environments due to its durability and resistance. The alloy's composition helps prevent corrosion, making it an excellent choice for marine applications. Regular maintenance will help maximize its longevity.

Is Aluminum Suitable for Underwater Applications?

Aluminum is a durable metal often used for underwater applications due to its lightweight nature and corrosion resistance. Its durability and performance underwater make it a suitable choice for various marine environments.

Does Titanium Rust or Corrode in Water?

In water, titanium's durability and corrosion resistance shine. This metal won't rust or corrode easily underwater due to its protective oxide layer. Titanium is a top choice for applications requiring long-term performance in aquatic environments.

How Does Copper Withstand Harsh Weather Conditions?

To understand how copper withstands harsh weather conditions, consider its durability and corrosion resistance. Copper's natural properties and oxide layer formation protect it from environmental damage, enabling it to maintain structural integrity and aesthetics over time.

Is Zinc Effective in Preventing Water Damage on Metal Surfaces?

Zinc coating on metal surfaces is effective in preventing water damage. It forms a protective layer that acts as a barrier against moisture, thereby enhancing the metal's durability. This method is widely used in various industries for corrosion resistance.

Conclusion

To sum up, when evaluating waterproof metals, stainless steel, aluminum, titanium, copper, and zinc are all viable options. Each of these metals offers unique properties that make them resistant to water and corrosion, making them ideal choices for various applications.

Whether it's stainless steel's durability, aluminum's lightweight nature, titanium's corrosion resistance, copper's weathering capabilities, or zinc's protective barrier, there's a waterproof metal for every need. Choose wisely based on your specific requirements and enjoy the benefits of a reliable, water-resistant material.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.