What Makes Jewelry Waterproof?

Waterproof Metals

In addition to being waterproof metals, stainless steel and titanium are renowned for their excellent resistance to water and corrosion. These metals' durability arises from their unique chemical compositions and the properties of their metal alloys.

Stainless steel, for instance, contains chromium, which forms a passive layer of chromium oxide on the surface. This layer acts as a barrier, preventing water and oxygen from penetrating and causing rust. This inherent corrosion resistance makes stainless steel a top choice for waterproof jewelry.

Titanium, on the other hand, boasts a remarkable strength-to-weight ratio and is highly resistant to corrosion. Its corrosion resistance stems from the formation of a thin, stable oxide layer on its surface when exposed to water and air. This protective layer effectively shields the metal from further oxidation, ensuring its longevity even in harsh environments. Additionally, titanium's biocompatibility makes it ideal for individuals with sensitive skin.

Protective Coatings

Protective coatings play an essential role in enhancing the water resistance of jewelry by creating an impermeable barrier against moisture and environmental contaminants. These coatings act as a shield, ensuring that water and corrosive elements don't penetrate the surface of your jewelry, thereby extending its lifespan and maintaining its aesthetic appeal.

Nanotechnology coatings are at the forefront of this innovation. They consist of ultra-thin layers, often mere nanometers thick, which adhere to the jewelry's surface at a molecular level. This creates an exceptionally robust barrier that's both durable and transparent, allowing your jewelry to retain its original brilliance. By employing nanotechnology, jewelers can offer superior protection without altering the look or feel of the piece.

Polymer seals are another effective method for waterproofing jewelry. These seals involve applying a synthetic resin, which hardens to form a protective layer. Polymers, known for their flexibility and resistance to water, provide a resilient coating that can withstand daily wear and tear. They're particularly useful for pieces with intricate designs or moving parts, where a more adaptable sealant is necessary.

Advanced Plating Techniques

Advanced plating techniques provide an effective solution for enhancing the water resistance of jewelry by applying a thin, durable layer of protective metal. One cutting-edge method involves nanotechnology applications, where nanoparticles form a compact, cohesive barrier against moisture. This layer is created through a process that guarantees uniform distribution of particles, resulting in a consistent, high-quality finish. Nanotechnology not only boosts water resistance but also improves scratch resistance and overall durability.

Ion plating is another advanced technique that greatly enhances the water resistance of jewelry. In this process, metal ions are vaporized and then accelerated in a vacuum chamber, allowing them to bond at a molecular level with the jewelry's surface. This creates an exceptionally strong and adherent coating. Ion plating offers several benefits, including increased hardness, enhanced corrosion resistance, and a lustrous appearance that lasts longer than traditional plating methods.

Sealed Settings

Sealed settings play a critical role in enhancing the water resistance of jewelry by creating an impermeable barrier that guarantees moisture ingress prevention. In these settings, each component of the jewelry piece is meticulously enclosed using advanced sealant materials. These materials, often composed of specialized resins or silicone compounds, provide a robust moisture barrier. They're designed to withstand prolonged exposure to water, thereby maintaining the integrity of the jewelry's internal structure and aesthetics.

When you examine a sealed setting, you'll notice the precision with which the sealant is applied. The sealant materials are carefully chosen to make certain they adhere perfectly to the jewelry's surface, filling any microscopic gaps that could allow water to penetrate. This process often involves a multi-stage application, where each layer of sealant is cured under controlled conditions to maximize its effectiveness.

Moreover, the durability of these moisture barriers is critical to the longevity of the jewelry. By preventing water from seeping in, sealed settings protect against potential damage such as corrosion, discoloration, and weakening of structural components. This meticulous approach guarantees that your jewelry remains both beautiful and functional, even in challenging environments.

Innovative Designs

You'll find innovative designs are important for waterproof jewelry.

Sealed metal coatings prevent oxidation, while waterproof gem settings guarantee stones remain secure.

Additionally, durable chain materials resist corrosion, providing longevity and resilience.

Sealed Metal Coatings

Innovative designs in jewelry often employ metal coatings that are meticulously sealed to prevent water ingress and guarantee durability. By applying a specialized coating, you can achieve significant corrosion resistance, which is essential in maintaining the integrity and appearance of your jewelry.

Metal sealing involves creating a barrier that not only repels water but also blocks oxygen and other elements that may cause oxidation and tarnishing. The process of metal sealing typically includes the application of a thin, uniform layer of protective material. This layer can be applied through methods like electroplating or vapor deposition, ensuring complete coverage and adherence to the base metal.

You might notice that jewelry with sealed coatings maintains its luster and structural integrity much longer than unsealed pieces. You should also consider the types of metals and coatings used. For instance, rhodium plating on white gold or silver creates a highly reflective, durable surface that's resistant to scratches and corrosion.

Additionally, advanced polymer coatings have emerged as robust alternatives, offering flexibility and resistance to environmental factors. These sealed metal coatings ensure that your jewelry not only remains waterproof but also retains its aesthetic appeal over time.

Waterproof Gem Settings

Modern waterproof gem settings utilize advanced sealing techniques to guarantee that water doesn't penetrate and damage the delicate structure of the gemstones. These innovative designs focus on precise gem placement and setting depth to create an impermeable barrier. The key is in the meticulous engineering of the sealant materials and the precision with which the gems are inserted into the settings.

When it comes to gem placement, ensuring that the gemstone is seated perfectly within the setting is essential. Any gaps or misalignments can allow water to seep in, potentially harming the gem. To prevent this, high-precision machinery is often employed to achieve a flawless fit.

The setting depth also plays a critical role in waterproofing. By embedding the gemstone at a strategic depth, designers can minimize exposure to water and other environmental factors. Shallow settings might look attractive but can leave the gem vulnerable. On the other hand, deeper settings provide a more robust protective layer, enhancing the waterproof capabilities.

Durable Chain Materials

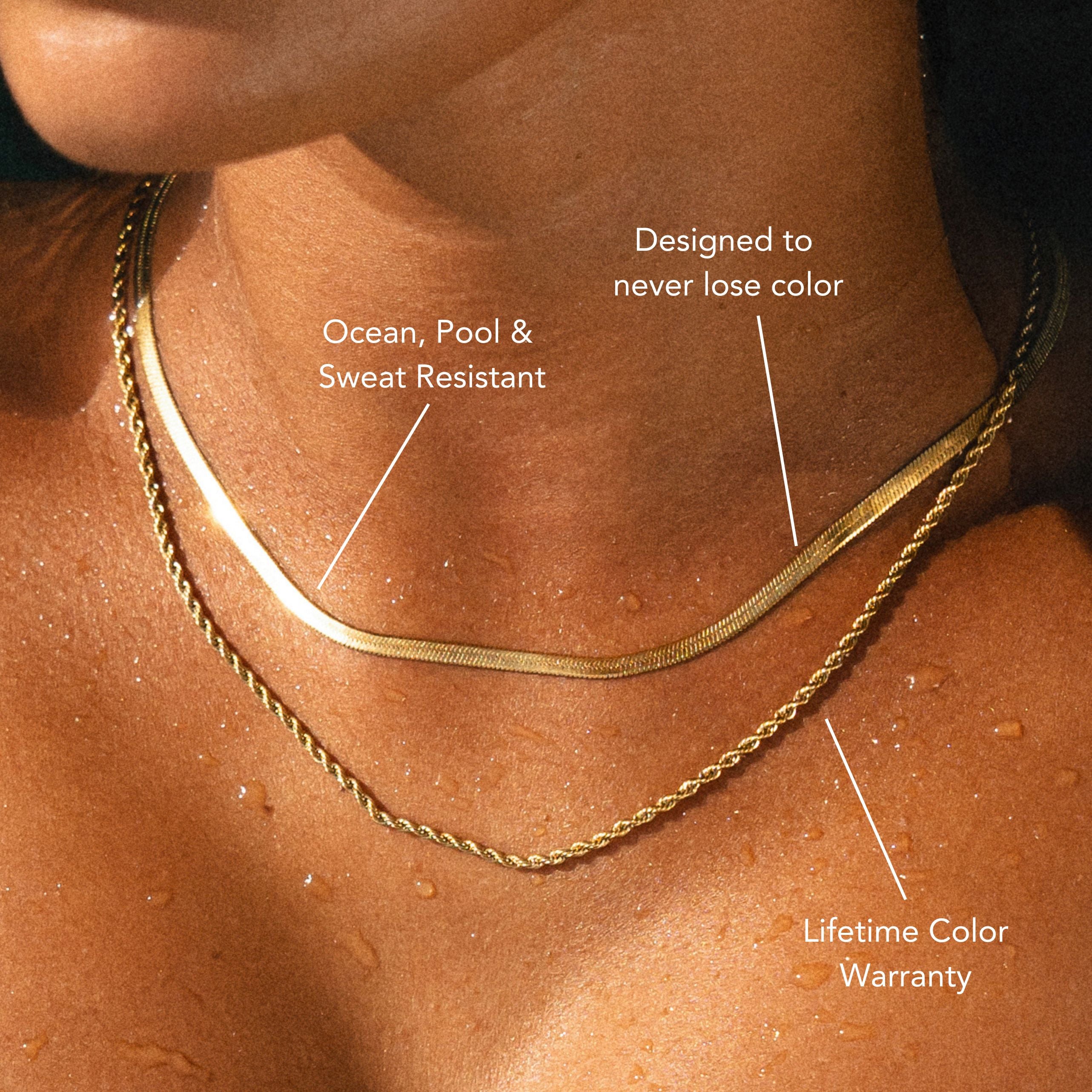

Designing durable chain materials for waterproof jewelry requires the use of high-strength alloys and advanced manufacturing techniques. You need to focus on materials like titanium and stainless steel, known for their corrosion resistance and strength.

Titanium chains, for example, are lightweight yet incredibly strong, making them ideal for active individuals. The titanium's natural oxide layer provides an excellent barrier against water and other corrosive elements.

Stainless steel, on the other hand, offers a blend of strength, durability, and resistance to tarnish. It's composed of iron, carbon, and chromium, the latter forming a passive film of chromium oxide that prevents surface corrosion. When crafting stainless steel chains, precision welding and seamless links are essential to ensure no weak points where water can seep through.

Both materials benefit from advanced manufacturing techniques like laser cutting and 3D printing. These methods allow for intricate designs without compromising structural integrity.

Additionally, using high-strength alloys in your jewelry means the chains can withstand daily wear and tear, including exposure to water, sweat, and even chemicals.

Testing for Waterproofing

To assess waterproofing in jewelry, you should employ rigorous laboratory testing methods that simulate real-world conditions. Adhering to established water resistance standards guarantees consistency and reliability in results.

Additionally, evaluating the durability under pressure helps determine the jewelry's long-term performance in aquatic environments.

Laboratory Testing Methods

How do scientists rigorously assess jewelry's waterproofing capabilities in laboratory settings? They use precise, controlled testing methods such as the salt spray and immersion test.

The salt spray test exposes jewelry to a highly corrosive saline environment to mimic long-term exposure to sweat or seawater. This test involves placing the jewelry in a chamber where it's continuously sprayed with a saline solution. The duration can range from hours to days, allowing scientists to observe any signs of corrosion or degradation.

The immersion test is another critical method. Here, jewelry is submerged in water for extended periods to test its resistance to water infiltration. Scientists often use distilled water to maintain constant parameters and avoid introducing variables that could affect the results. The immersion test can be conducted at various depths and temperatures, simulating different real-world conditions.

Both tests provide essential data on how well jewelry can withstand prolonged exposure to moisture without compromising its structural integrity or appearance. By employing these rigorous laboratory methods, scientists can make certain that the jewelry you wear isn't only beautiful but also durable enough to resist water damage.

Water Resistance Standards

When evaluating jewelry for waterproofing, industry standards like the IP Code (Ingress Protection) and ISO 22810 establish rigorous benchmarks to guarantee durability and resistance to water exposure. The IP ratings, a two-digit grading system, quantify the protection levels. The first digit indicates the degree of protection against solid particles, while the second digit specifies resistance to liquid ingress. For instance, an IP68 rating signifies robust protection against dust and prolonged water submersion.

ISO 22810, on the other hand, focuses on water resistance in everyday use. It requires jewelry to withstand specified pressures without leaking. Testing involves exposing items to varying water depths and pressures to measure their resilience. Surface tension is a critical factor in these tests, as it determines water's ability to penetrate the material. Jewelry must effectively repel water molecules to pass these standards.

You need to understand how the interplay of materials, design, and construction techniques contribute to achieving high IP ratings and ISO certification. By adhering to these water resistance standards, manufacturers guarantee that their jewelry can endure real-world conditions, providing you with reliable, waterproof pieces.

Durability Under Pressure

Jewelry undergoes rigorous testing to confirm it remains durable under pressure, simulating real-world conditions to validate its waterproof capabilities. You need to verify that the piece can withstand various depths and pressures without compromising either its appearance or functionality.

This involves subjecting the jewelry to hydrostatic pressure tests where it's submerged in water and exposed to increased pressures to evaluate pressure resistance. During these tests, you measure the structural integrity of the jewelry by looking for signs of water ingress, material deformation, or mechanical failure. Any breach in the piece's construction could lead to water penetration, which can damage internal components or cause corrosion.

By meticulously examining the jewelry under these stringent conditions, you can establish its ability to remain watertight. To further validate durability, you might employ cyclic pressure testing, where the jewelry is repeatedly exposed to varying pressure levels. This simulates the repeated stress it would encounter in daily use.

Through these thorough assessments, you're ensuring that the jewelry not only meets but exceeds industry standards for waterproofing, guaranteeing that it maintains its integrity and functionality under all conditions.

Care and Maintenance

Proper care and maintenance greatly extend the lifespan of your waterproof jewelry, ensuring it remains both functional and attractive. Regular cleaning practices are essential. Use a soft-bristled brush and mild soap to gently scrub away any accumulated dirt or oils. Avoid harsh chemicals, as they can damage the protective coatings that contribute to the jewelry's waterproof properties. Rinse thoroughly with clean water and pat dry with a soft cloth to prevent water spots.

Storage solutions also play an important role. Store your waterproof jewelry in a dry, cool place to minimize exposure to humidity, which can degrade materials over time. Use silica gel packets to absorb excess moisture and keep tarnish at bay. For added protection, consider individual compartments or soft cloth pouches to prevent scratches and maintain the integrity of any waterproof seals.

Periodic inspections are crucial. Check for signs of wear, such as loose stones or weakened clasps, and address these issues promptly. Ensuring your jewelry remains in excellent condition involves not only daily care but also occasional professional maintenance.

A jeweler can recalibrate waterproof features and perform deep cleaning, ensuring your pieces continue to withstand environmental pressures.

Conclusion

To sum up, ensuring your jewelry is waterproof involves selecting appropriate metals and applying protective coatings. Advanced plating techniques and sealed settings further enhance water resistance.

Innovative designs also play an essential role, while rigorous testing confirms the jewelry's durability. Proper care and maintenance are essential to preserve these protective measures.

By understanding and utilizing these scientific principles, you can enjoy your waterproof jewelry without compromising its beauty or integrity.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.