What Is 18k PVD Plating?

Understanding 18k Gold

18k gold consists of 75% pure gold alloyed with other metals to enhance its strength and durability. When evaluating gold purity, understanding the karat system is important. Pure gold, or 24k gold, is too soft for everyday wear. By alloying gold with other metals like copper or silver, 18k gold achieves a balance between purity and practicality.

Compared to 14k gold, which contains about 58.3% pure gold, 18k gold offers a richer color and higher value due to its greater gold content. This makes 18k gold more desirable for high-end jewelry, where both appearance and durability matter. However, it's less durable than 14k gold, making it more prone to scratches and wear.

When you choose 18k gold, you're opting for a metal that combines significant gold purity with enhanced strength. This balance affects not only the aesthetic appeal but also the longevity of your jewelry pieces. Understanding these aspects helps you make informed decisions, whether you're purchasing a new piece or considering the maintenance of existing ones.

The PVD Plating Process

In the PVD plating process, a thin layer of gold is deposited onto a substrate through a vacuum-based method, ensuring a durable and high-quality finish. You start by placing the substrate inside a vacuum chamber. The vacuum environment is essential as it eliminates contaminants that could compromise the coating's integrity.

Next, the coating materials, in this case, 18k gold, are vaporized. This vaporization often occurs through techniques like sputtering or evaporation, where the gold is either bombarded with ions or heated until it turns into a gas. The vacuum chamber allows the gold atoms to travel uninhibited and deposit uniformly on the substrate.

During deposition, the substrate may be rotated to achieve an even coating. The vacuum chamber's controlled conditions also enable precise adjustments to factors like temperature and pressure, which are crucial for achieving the desired thickness and adherence of the gold coating.

Once the gold atoms settle on the substrate, they form a thin, adherent layer. This layer isn't only visually appealing but also resistant to wear and corrosion. By following these steps meticulously, you ensure the resulting 18k PVD plating is both aesthetically pleasing and functionally robust.

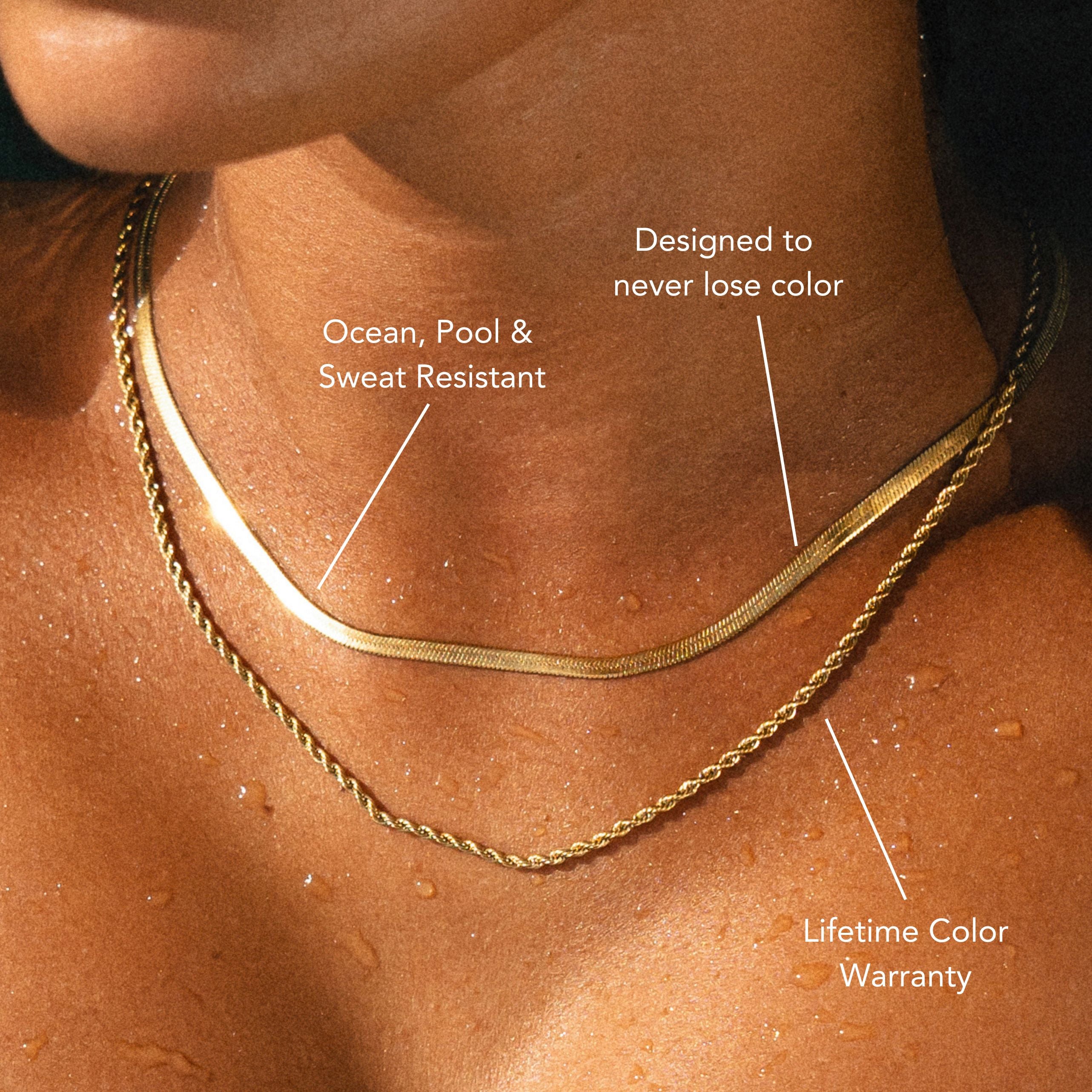

Benefits of 18k PVD Plating

Why should you consider 18k PVD plating for your projects? The primary reason is enhanced durability. 18k PVD (Physical Vapor Deposition) plating creates a strong, wear-resistant layer that greatly extends the lifespan of the coated item. This durability guarantees that your projects maintain their appearance and functionality over time, reducing the need for frequent replacements or repairs.

Another compelling advantage is cost efficiency. While the initial cost of 18k PVD plating might be higher than traditional coating methods, the long-term savings are substantial. The enhanced durability means fewer resources spent on maintenance and replacements, translating into reduced operational costs. Additionally, PVD processes are more environmentally friendly, potentially lowering costs related to waste disposal and regulatory compliance.

Furthermore, the precision of the PVD process ensures a uniform coating, which not only enhances aesthetic appeal but also provides consistent performance across all coated surfaces. This uniformity is critical in applications requiring exacting standards, thereby reducing the likelihood of defects and associated costs.

Common Uses and Applications

Due to its exceptional durability and aesthetic appeal, 18k PVD plating finds extensive use across various industries, including jewelry, automotive, and electronics.

In the jewelry sector, 18k PVD plating is commonly applied to luxury watches. This process not only enhances the visual allure of the timepieces but also greatly extends their lifespan by providing a robust protective layer resistant to scratches and tarnish. The result is a high-end product that maintains its pristine condition over time.

In the automotive industry, 18k PVD plating is frequently used on automotive parts. Components such as trim, badges, and interior accents are often coated with this durable finish. This application ensures these parts can withstand harsh environmental conditions, including exposure to heat, moisture, and road debris, without compromising their appearance or functionality. The PVD coating also adds a touch of sophistication to the vehicle's overall aesthetic.

In electronics, 18k PVD plating is utilized to coat various device housings and connectors. This not only provides an elegant finish but also enhances the component's resistance to wear and corrosion. Consequently, the devices exhibit improved longevity and reliability, making them more appealing to consumers.

Caring for PVD Plated Items

To uphold the integrity and appearance of 18k PVD plated items, make sure you clean them regularly with a soft, non-abrasive cloth. This method guarantees that surface particles and oils are removed without scratching the coating. For deeper cleaning, use a mild soap solution. Submerge the item briefly, then gently scrub with a soft brush, avoiding harsh chemicals which can degrade the PVD layer.

Effective storage tips are also essential. Store PVD plated items in individual pouches or compartments to prevent contact with other jewelry. This minimizes the risk of abrasion and maintains the luster. Avoid humid environments, as moisture can accelerate tarnishing. A silica gel packet in your storage area can help control humidity.

When wearing PVD plated items, avoid exposure to harsh chemicals like chlorine or household cleaners. These substances can compromise the plating. Remove items before engaging in activities that may cause physical damage, such as exercising or gardening.

Conclusion

To sum up, comprehending 18k PVD plating provides you with valuable insights into its process and benefits. The technique combines the allure of 18k gold with the durability of PVD, resulting in high-quality, long-lasting finishes.

You'll find this method widely used in various industries, from jewelry to electronics. By properly caring for PVD plated items, you guarantee their longevity and maintain their aesthetic appeal. Embrace 18k PVD plating for its superior performance and elegant appearance.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.