What is PVD Coating on Jewelry?

Understanding PVD Coating

PVD coating, or Physical Vapor Deposition, is a process where a solid material is vaporized in a vacuum and then deposited onto a substrate, forming a thin, durable layer. This coating technology is pivotal in various industries due to its ability to enhance surface properties such as hardness, wear resistance, and corrosion resistance. You'll find PVD applications in sectors ranging from aerospace to decorative items like jewelry.

When considering PVD coating for jewelry, it's crucial to understand its advantages. This process allows for a highly controlled deposition of materials like titanium nitride or zirconium nitride, resulting in a uniform, aesthetically pleasing finish. The technology is versatile, enabling the creation of different colors and finishes without compromising the substrate's integrity. Additionally, PVD coatings are hypoallergenic, making them suitable for people with sensitive skin.

In analytical terms, PVD coating technology provides a superior alternative to traditional plating methods. The layer formed isn't only thinner but also stronger and more durable. This translates to less maintenance and longer-lasting pieces.

The PVD Coating Process

The coating process involves vaporizing the chosen material in a high-vacuum environment and then precisely depositing it onto the jewelry substrate. To start, you place the jewelry inside a vacuum chamber, which is then evacuated to create a low-pressure environment. This step is essential for preventing contamination and ensuring a clean deposition.

Next, sputtering targets, which are made of the coating material, are introduced into the chamber. These targets are bombarded with high-energy ions, causing atoms to be ejected from the target material. This phenomenon is known as sputtering. The ejected atoms then travel through the vacuum and condense onto the jewelry, forming a thin, uniform layer.

During this process, parameters such as temperature, pressure, and ion energy are meticulously controlled to achieve the desired coating thickness and properties. Advanced techniques like magnetron sputtering may be employed to enhance the deposition rate and coating quality.

Benefits of PVD Coating

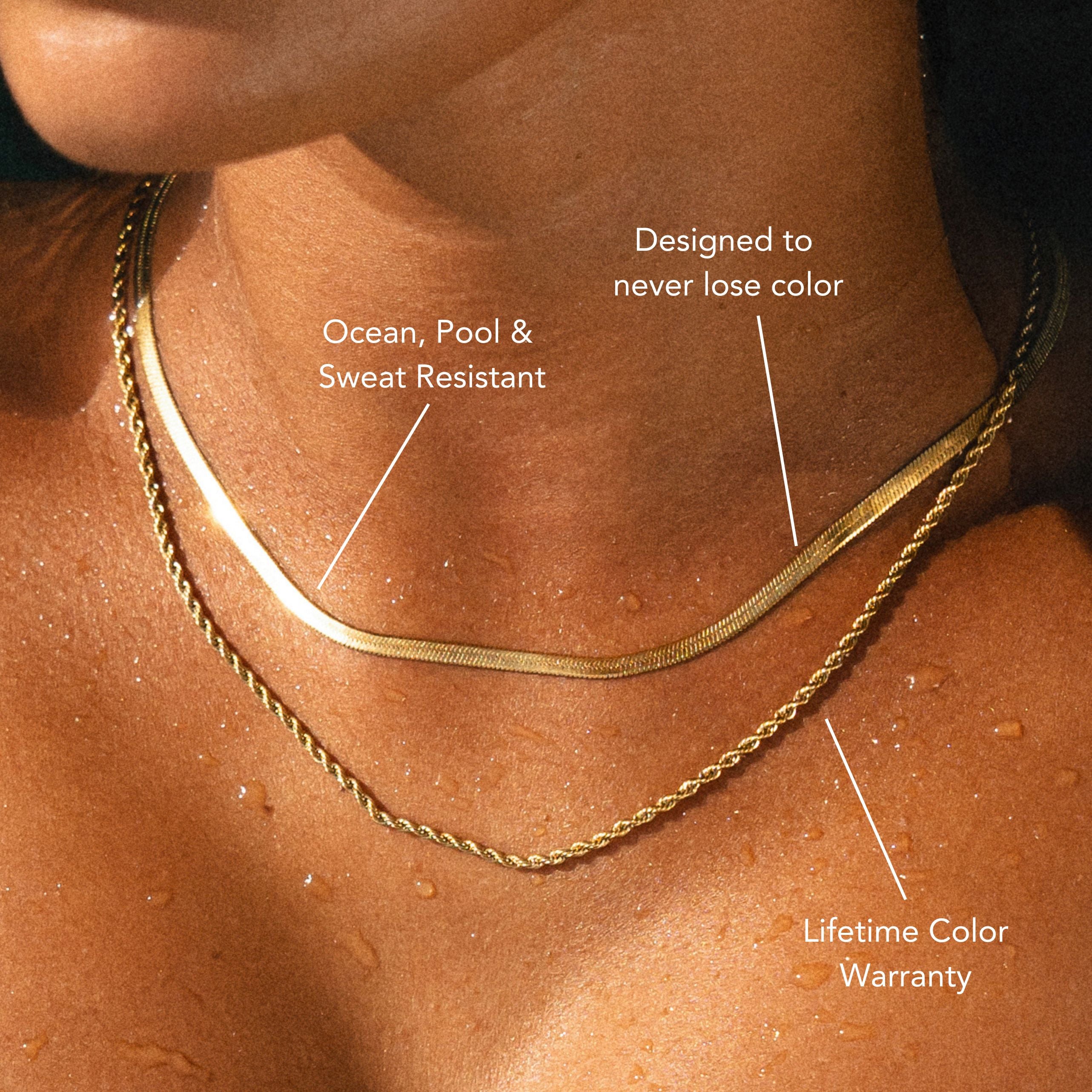

By harnessing the precision of the PVD coating process, you gain access to a multitude of benefits for jewelry, including enhanced durability, resistance to tarnish, and a visually appealing finish.

The durability advantage is paramount. PVD, or Physical Vapor Deposition, creates a hard, wear-resistant layer that greatly extends the lifespan of your jewelry. This means your pieces remain pristine and free from scratches or abrasions for a much longer period compared to traditional coatings.

Moreover, PVD coating offers excellent resistance to tarnish. Unlike other coatings that might degrade over time, PVD maintains its integrity, ensuring your jewelry retains its luster and brilliance. This is particularly advantageous for items exposed to harsh environments or frequent handling.

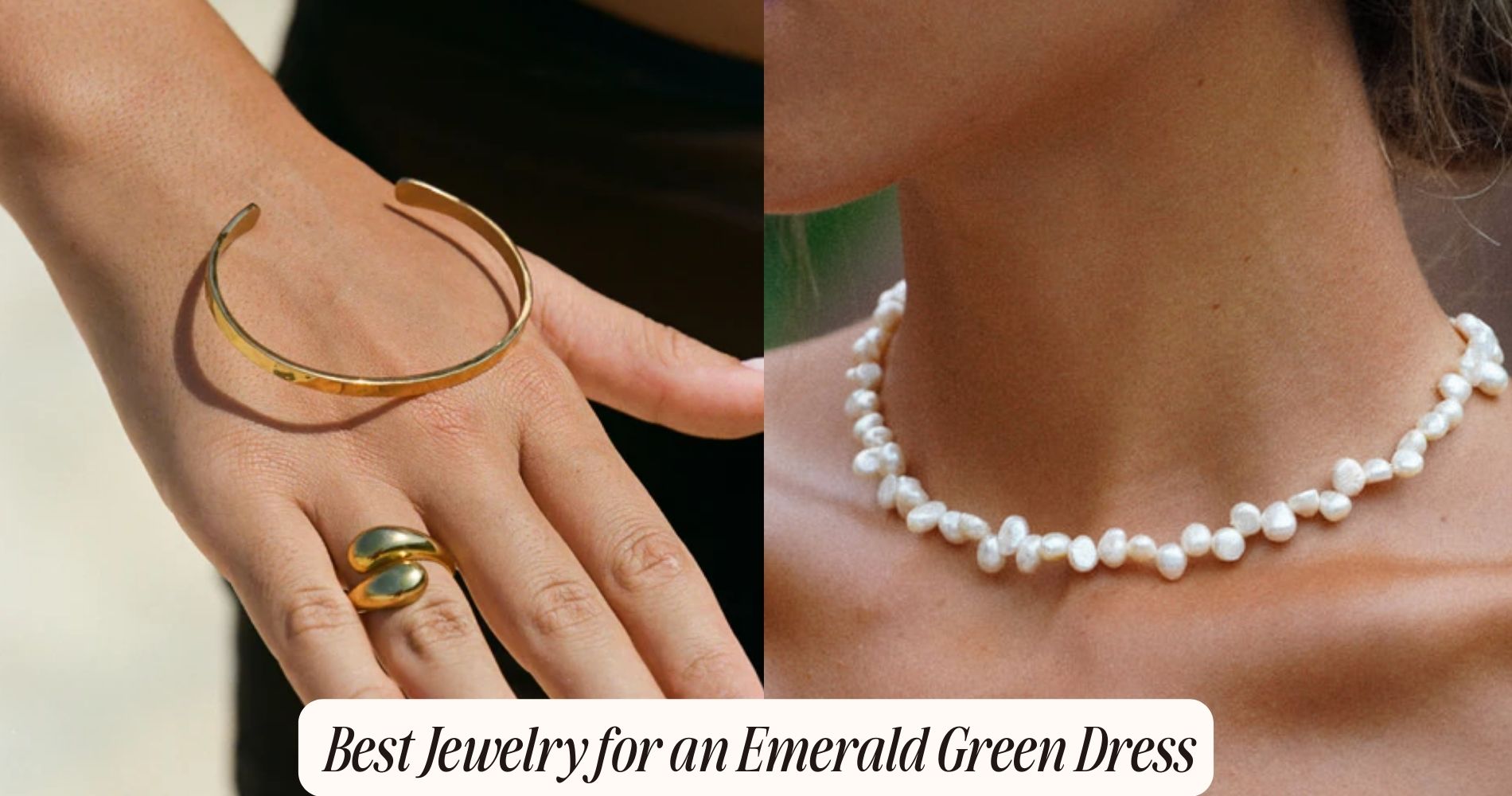

The process also provides a remarkable color variety. PVD coatings can achieve a wide spectrum of colors, from classic gold to vibrant hues like blue or rose gold, all with exceptional consistency and depth. This flexibility allows you to create unique, personalized pieces without compromising on quality.

Comparing PVD to Other Finishes

When comparing PVD coating to other finishes, you'll notice significant differences in durability, color variety, and resistance to environmental factors. PVD (Physical Vapor Deposition) stands out for its superior hardness and scratch resistance, making it a long-lasting choice for jewelry.

Traditional plating methods, like gold or rhodium plating, tend to wear off more quickly, necessitating frequent reapplication.

In terms of aesthetic appeal, PVD offers a broader range of colors, including gold, rose gold, black, and even iridescent hues. These colors aren't only vibrant but also more resistant to tarnishing and fading over time. Contrarily, traditional finishes may lose their luster and require frequent polishing to maintain their appearance.

From a cost comparison perspective, PVD coating can be more expensive initially due to the advanced technology required. However, its longevity and minimal maintenance needs can make it more cost-effective in the long run. Traditional plating methods might seem cheaper at first glance, but the recurring costs of reapplication and maintenance add up over time.

Caring for PVD-Coated Jewelry

To maintain the pristine condition of PVD-coated jewelry, gently clean it with a soft cloth and avoid harsh chemicals. Start by using a microfiber or lint-free cloth to remove dirt and oils. For more thorough cleaning methods, use lukewarm water mixed with a mild soap. Dip the cloth in the solution, wipe the jewelry, and then dry it with a clean cloth. Avoid using abrasive materials or chemical cleaners, as these can damage the PVD coating.

When it comes to storage tips, make sure the jewelry is kept in a dry, cool environment. Store each piece separately in a fabric-lined jewelry box or pouch to prevent scratches and other physical damage. Avoid placing PVD-coated jewelry in direct sunlight or humid areas, as prolonged exposure can affect its appearance.

Moreover, limit the jewelry's contact with cosmetics, perfumes, and lotions, as these substances can degrade the coating over time. It's advisable to put on PVD-coated jewelry last when dressing and remove it first when undressing.

Following these precise cleaning methods and storage tips, you can greatly extend the life and luster of your PVD-coated jewelry.

Conclusion

To conclude, PVD coating greatly enhances jewelry's durability and appearance.

By grasping the PVD process, you'll recognize its superior wear resistance and longevity compared to other finishes.

To maintain your PVD-coated jewelry, avoid abrasive materials and harsh chemicals.

This advanced technology guarantees your pieces remain vibrant and scratch-resistant, making it a cost-effective and aesthetically pleasing choice for long-term use.

Ultimately, PVD coating is a precise and reliable method for preserving your jewelry's pristine condition.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.