Precious Metal for Jewelry: What Really Matters

Choosing a precious metal for jewelry is best approached with an engineer’s mindset—match karat, alloy, and finish to how you’ll wear the piece, the color you prefer, and the level of upkeep you’re comfortable with. Pure 24k gold offers exceptional luster, while 18k and 14k alloys increase hardness and scratch resistance for everyday wear. Yellow gold is stable and low-maintenance; white gold requires rhodium and may cause irritation if nickel-based; rose gold is especially durable thanks to its copper content. Platinum is dense, hypoallergenic, and highly secure for stones, while palladium offers similar benefits at a lighter weight. Sterling silver provides shine at a lower cost but needs anti-tarnish care. For sensitive skin and daily comfort, Hypoallergenic Jewelry helps eliminate common irritants. Always verify hallmarks via assay or XRF, consider ethical sourcing (recycled, RJC, Fairmined), and factor in your lifestyle when choosing the right metal for each piece and budget.

Understanding Purity: Karats, Fineness, and Alloys

Purity sets the baseline for a precious metal’s performance, value, and appearance. You gauge gold content with the karat scale: 24k is fundamentally pure, while 18k, 14k, and 10k indicate decreasing gold proportion.

Fineness expresses the same concept as parts per thousand (e.g., 999, 750, 585). As purity drops, hardness, wear resistance, and cost typically improve, but intrinsic value per gram declines.

You should analyze alloy composition because it dictates mechanical properties, workability, and corrosion behavior. Copper, silver, palladium, nickel, and zinc are common additions that tune yield strength, ductility, and casting flow.

For rings and bracelets, prioritize alloys with higher hardness and fatigue resistance; for intricate settings, favor alloys with good malleability and solder compatibility.

Always verify hallmark accuracy with assay or XRF testing.

Gold Compared: Yellow, White, and Rose Pros and Cons

Three dominant gold colors—yellow, white, and rose—stem from distinct alloy systems that trade aesthetics against performance.

You’ll see yellow gold benefits in its inert behavior, warm hue, and easy maintenance; copper-silver blends preserve ductility and make resizing predictable.

White alloys achieve a cooler tone via nickel, palladium, or manganese, but white gold drawbacks include potential nickel sensitivity, rhodium replating needs for brightness, and higher work-hardening that complicates repairs.

Rose alloys push copper higher, driving rose gold popularity for its saturated blush, strong wear resistance, and vintage-to-modern versatility.

For color matching, yellow complements warm stones and vintage cuts; white amplifies colorless diamonds and cool gems; rose flatters pink-to-purple palettes and skin tones.

Choose karat and alloy family to balance hardness, color stability, and serviceability.

Platinum Versus White Gold: Color, Weight, and Wear

While both metals target a cool, silvery aesthetic, platinum and white gold diverge in color neutrality, mass, and surface behavior that you’ll notice in daily wear and service.

Platinum is intrinsically white; it doesn’t rely on rhodium plating, so color remains consistent through refinishes. White gold, alloyed with nickel or palladium plus rhodium topcoat, trends slightly gray or warm as plating thins, requiring periodic re-plating to maintain brightness.

You’ll feel density differences. Platinum’s higher specific gravity yields a heftier, more substantial wear. That mass aids stone security when paired with platinum’s work-hardening and deformation behavior: it displaces rather than losing metal, preserving prongs over time.

Key platinum benefits include hypoallergenic purity, stable color, and longevity in settings. White gold offers crisp initial whiteness, lower cost, and lighter feel, with scheduled maintenance.

Palladium’s Place: Lightweight Luxury and Practicality

Looking for platinum’s cool hue without the heft? Choose palladium. You’ll get a noble, naturally white metal that doesn’t need rhodium plating, holds a crisp polish, and resists tarnish.

Its density is about 12 g/cm³—roughly 40% lighter than platinum—so larger designs feel comfortable and balanced. Its hardness supports fine prong work, secure bezels, and thin pavé with reduced deformation.

Palladium benefits include hypoallergenic performance, stable color, and excellent wear over time. It’s also highly workable for laser welding and precision casting, producing clean micro-details.

For ethical assurance, evaluate palladium sourcing: prefer recycled content, conflict‑free audits, and traceable supply chains from primary PGM mines with robust environmental controls.

For stones, palladium’s stiffness maintains seat integrity, while its thermal conductivity aids controlled heat management during repairs.

Silver Smartly: When Sterling Shines and When It Doesn’t

Palladium offers lightweight strength, but sterling silver earns a place when you want bright reflectivity, fine detail, and accessible cost. You get crisp casting fidelity, clean solder seams, and a bright white tone that suits high-polish and satin finishes.

Evaluate alloy types: standard 925 sterling balances hardness and workability; argentium-style alloys add germanium for higher tarnish resistance; de-ox variants reduce firescale and ease finishing.

Choose sterling when you need complex filigree, rapid prototyping to casting workflows, or budget-sensitive collections with premium look. Avoid it for exposure to chlorinated water, sulfur-rich environments, or skin chemistries prone to rapid tarnish.

Practice sterling care: rinse after wear, dry fully, store airtight with anti-tarnish strips, and use non-abrasive cleansers. Specify rhodium flash selectively to stabilize color without masking character.

Durability and Scratch Resistance in Daily Life

Even outside the studio, durability lives in the microstructure: alloy composition, grain size, and work-hardening dictate how your piece resists dents, abrasion, and metal transfer from daily contact.

You control everyday durability by choosing the right alloy and temper. Higher-karat gold deforms more; 14k or 18k with nickel-free white or palladium additions deliver better scratch resistance.

Platinum’s high toughness resists loss of material but displaces into “peen” rather than a bright scratch; periodic burnishing restores luster.

Fine-grain, cold-worked structures (e.g., forged or rolled) outperform annealed stock.

Rhodium on white alloys raises surface hardness, but it’s a coating—expect maintenance.

Prioritize profiles and finishes that hide marks: brushed textures, rounded edges, and bezel settings reduce visible wear from countertops, keys, and laptops.

Skin Sensitivities and Hypoallergenic Choices

Although aesthetics lead many choices, skin compatibility depends on alloy chemistry, surface condition, and corrosion behavior. If you’re prone to metal allergies, prioritize alloys with minimal sensitizers.

Nickel is the primary trigger; cobalt and brass (copper–zinc) can also provoke skin reactions under sweat and friction. Choose hypoallergenic materials: platinum (950 Pt–Ir or Pt–Ru), high-karat gold (18K+ with palladium whitening), titanium (grade 2 or 5), niobium, and surgical stainless steels labeled ASTM F138/F139.

Avoid ambiguous “nickel safe” claims; verify EN 1811 nickel-release compliance.

Skin environment matters. Low pH sweat and chlorides accelerate ion release, so reduce exposure during exercise and saltwater.

For jewelry care, rinse, dry, and keep surfaces smooth to limit crevice corrosion. Test new pieces on limited skin contact before extended wear.

Maintenance Realities: Rhodium Plating, Polishing, and Patina

While design draws attention, upkeep drives how precious metals look and wear over time. You should plan for rhodium plating on white gold: thickness (0.10–0.30 microns) dictates rhodium longevity, and abrasion rate depends on contact points—rings wear fastest.

Expect re-plating intervals of 12–36 months; extend cycles by avoiding chlorides, polishing wheels, and gritty debris.

Select polishing techniques by alloy and hardness. Use felt and 1–3 micron diamond for platinum; switch to rouge or alumina on high-karat gold to prevent orange peel.

Always finish with cross-cut, light pressure, and proper lubrication to limit mass loss and rounding.

Embrace or control patina. Platinum work-hardens, developing a gray luster; buff to mirror or maintain the satin.

Silver tarnish needs chemical dips, then gentle hand polish.

Ethics and Budget: Mined vs. Recycled vs. Lab-Grown

Because sourcing shapes both cost and conscience, you’ll choose among mined, recycled, and lab-grown metals and stones by weighing provenance, traceability, and total lifecycle impact against price.

For mined materials, verify chain-of-custody programs (RJC CoC, Fairmined, Fairtrade) and conflict-free documentation. Expect higher premiums when audits and community royalties are embedded into ethical sourcing.

Recycled metals reduce primary extraction impacts but don’t erase historic harms; prioritize suppliers with ISO-certified refining and segregation to prevent greenwashing.

Lab-grown diamonds and gemstones often lower price-per-carat and environmental load, but scrutinize energy mix, third-party LCA data, and disclosure standards (ISO 18323, SCS-007).

Align budget considerations with verification depth: request assay reports, origin statements, and supply-chain attestations.

Pay for transparency, not just claims, and choose the provenance you can document.

Lifestyle Matchmaking: Choosing Metals for Rings, Earrings, and More

Start with your daily wear patterns, then map metals to mechanical demands and skin chemistry.

If you’re hands-on, choose platinum or 18k palladium white gold for rings—high hardness, excellent malleability, and minimal nickel exposure. For earrings, prioritize hypoallergenic alloys: titanium, niobium, or 14k palladium white gold.

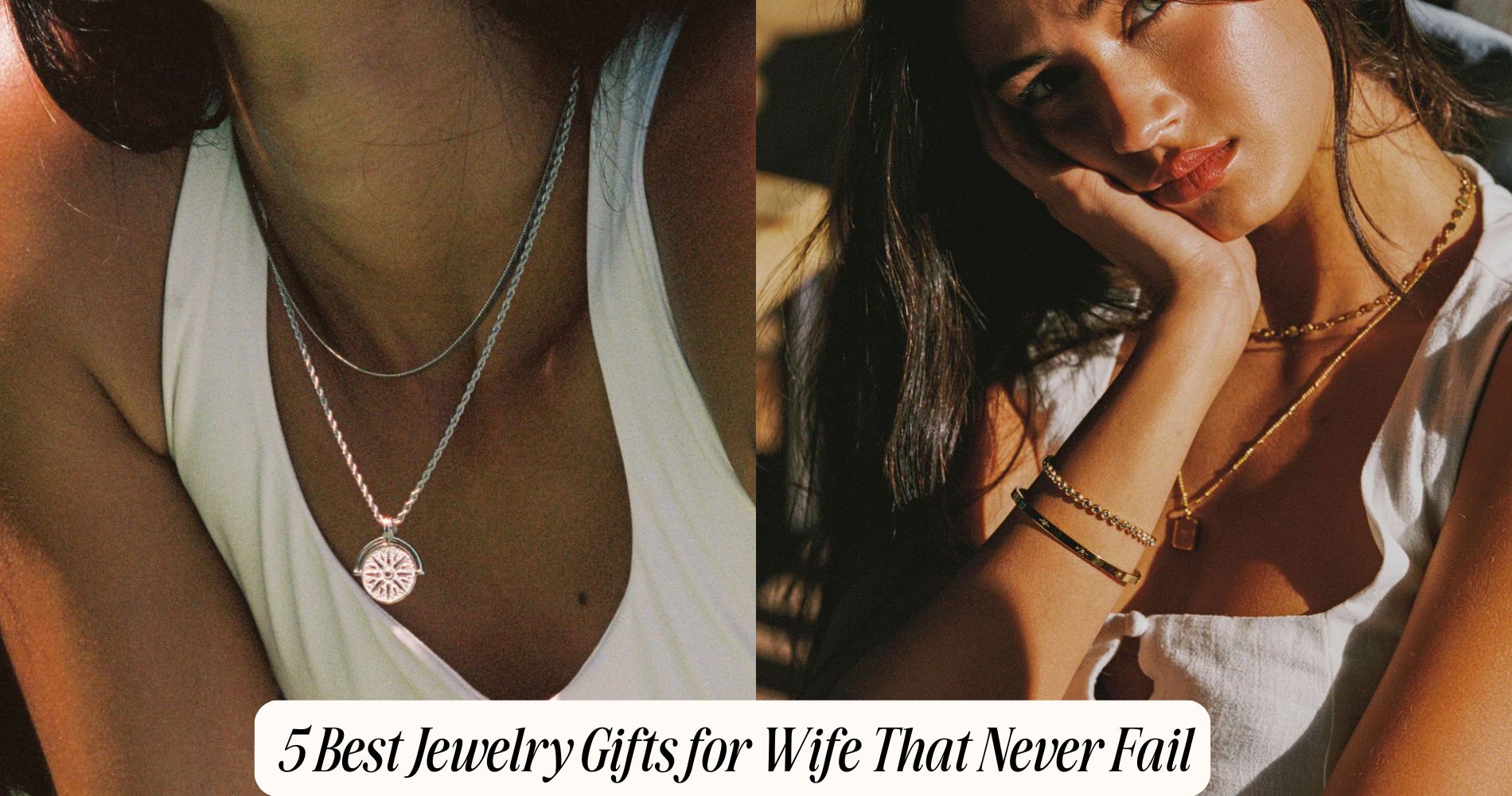

Necklaces and bracelets tolerate softer alloys; 18k yellow gold offers rich color with acceptable wear if you’re desk-bound.

Match finish to abrasion risk: brushed hides micro-scratches; high polish suits low-contact use.

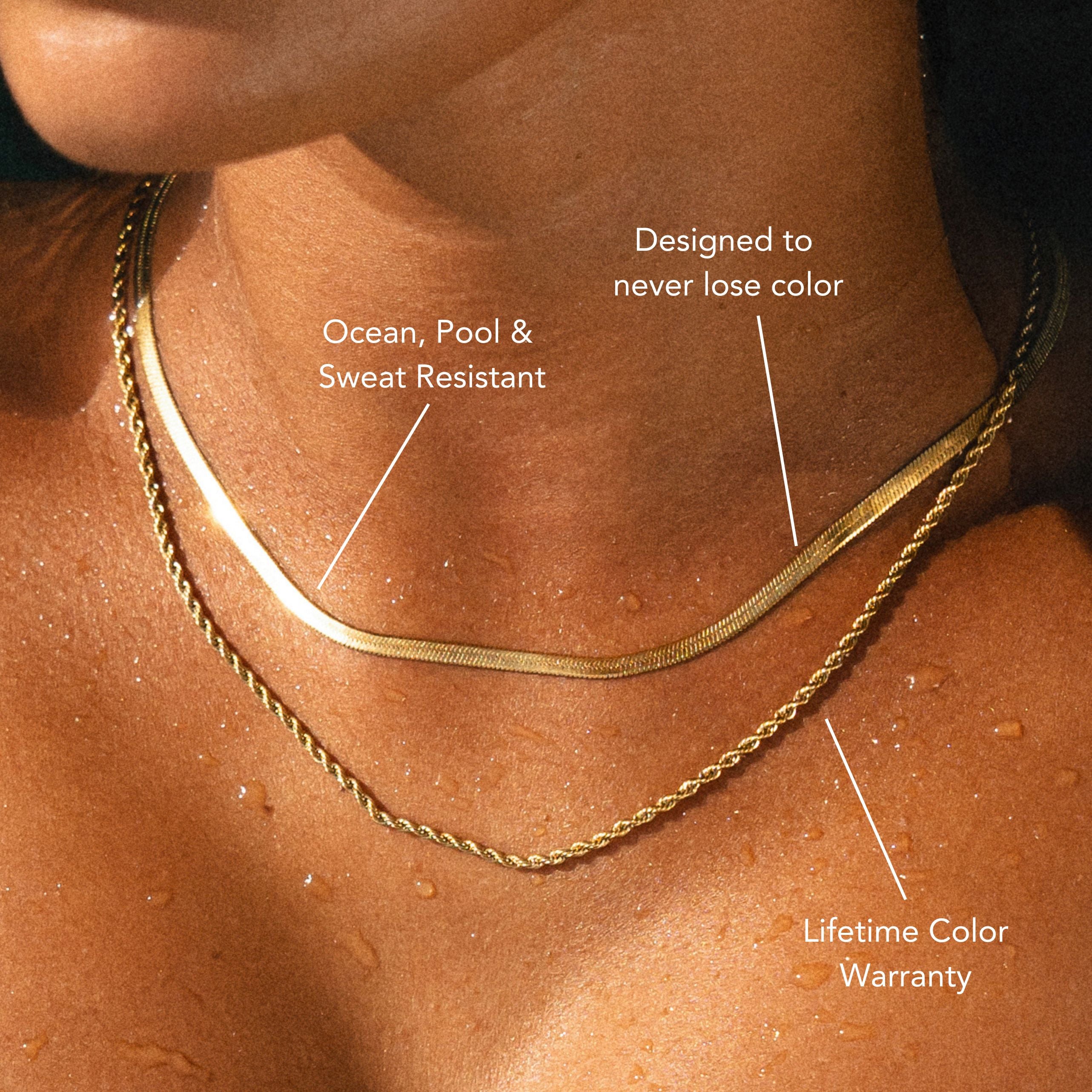

Consider sweat and chlorine exposure—rhodium-plated white gold needs periodic replating; avoid pools with silver.

Build metal combinations intentionally: platinum ring with titanium band, or silver earrings with gold necklace, to balance durability and personal style.

Test with short trials before committing.

Frequently Asked Questions

Can Precious Metals Affect Resale Value of Gemstone-Set Jewelry?

Yes. You’ll see precious metals greatly influence gemstone-set jewelry’s resale value. Metal purity, hallmarking, and weight track resale trends and market demand. Platinum and high-karat gold command premiums; mixed metals, plated settings, and uncertain assays depress liquidity, appraisal grades, and buyback bids.

How Do Metals Influence Engraving Clarity and Longevity?

Metals influence engraving clarity and longevity through metal hardness and compatible engraving techniques. You’ll get crisp, lasting cuts in harder alloys; softer metals engrave smoothly but wear faster. Choose laser for hard platinum, rotary for gold, deep relief for durability.

Are Certain Metals Safer for MRI or Medical Procedures?

Yes. You should prefer titanium and niobium for MRI compatibility; they’re nonferromagnetic and stable. Platinum and high-karat gold are generally safe. Avoid stainless steels, cobalt alloys, and unknown ferrous metals. For metal allergies, favor titanium, niobium, or platinum.

What Metals Perform Best in Extreme Hot or Cold Climates?

You’ll get best performance from platinum and titanium in extreme temperatures. Platinum resists creep; titanium maintains strength. For thermal stability, rhodium excels. You’ll value gold durability at heat-cycling interfaces. Leverage silver conductivity for cryogenic applications, but mitigate tarnish and thermal expansion.

How Do Metals Impact Ring Resizing Options and Limits?

Metals dictate ring resizing options via metal malleability and compatible resizing techniques. You’ll resize gold and platinum reliably; palladium’s harder. Titanium, tungsten, and stainless steel resist sizing. Soldered channels, tension settings, or brittle alloys limit upsizing; annealing and laser welding expand possibilities.

Conclusion

You’ve now got the metallurgy that matters. Weigh karat versus fineness, alloy content, and work-hardening. Compare gold colors by nickel/palladium/copper additions, and judge platinum’s density, malleability, and wear against white gold’s rhodium dependence. Consider palladium’s low mass and hypoallergenic edge, and sterling’s hardness and tarnish care. Match metals to skin sensitivities, upkeep tolerance, sourcing ethics, and budget. Finally, choose by use-case: rings need durability, earrings favor lightness, necklaces value color stability. Select the metal engineered for your life.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.