Understand the Advantages and Disadvantages of Gold Plating

Understanding the advantages and disadvantages of gold plating is crucial when considering its use. Gold plating offers distinct benefits, such as enhanced aesthetic appeal and corrosion resistance, which make products more attractive and durable. It also improves electrical conductivity, an essential feature in electronics. However, the disadvantages include higher costs due to fluctuating gold prices and environmental concerns tied to the hazardous chemicals used in the plating process. Additionally, thinner layers of gold plating may wear down quickly, affecting longevity. While gold plating increases perceived value and product differentiation, exploring alternatives like rhodium plating or gold-filled options may provide better durability and cost-effectiveness. For timeless and versatile designs, check out our Everyday Gold Necklace collection.

What Is Gold Plating?

Gold plating, often seen in project management and product development, refers to the practice of adding extra features or enhancements that exceed the original requirements. This phenomenon can arise from a desire to impress stakeholders or to enhance the perceived value of a product. You might encounter various gold plating techniques, such as incorporating unnecessary functionalities or embellishing design aspects that don't address core needs.

Historically, gold plating has roots in both craftsmanship and business practices, where artisans would add decorative elements to elevate a product's appeal. However, this historical significance highlights a recurring issue: while the intent may be to enhance quality, it often leads to increased costs and prolonged timelines.

The practice can stem from a misunderstanding of project scope or an overzealous commitment to perfection, resulting in features that may not align with user requirements.

Ultimately, understanding what gold plating entails allows you to critically evaluate its implications in project management and product development. It's important to discern when enhancements add value versus when they complicate the process and detract from the project's original goals.

Benefits of Gold Plating

Often, adding extra features can create unexpected advantages in project management and product development. Gold plating, while often seen as a risk, can also enhance the investment value of your project. By incorporating additional features or enhancements, you may boost the perceived value of your product, making it more attractive to potential buyers. This increased value can lead to higher returns on your investment, especially if those features align with current market demand.

Moreover, gold plating can differentiate your product in a competitive landscape. When you respond to specific market needs through additional functionalities, you cater to a wider audience, potentially increasing your customer base. This strategic move can also position your product as a leader in innovation, enhancing brand reputation and trust.

However, it's vital to balance the benefits with the associated risks of gold plating. If the additional features don't resonate with your target market, you may waste resources and time. Consequently, understanding market trends and consumer behavior is essential. By doing so, you can guarantee that your gold plating efforts translate into tangible advantages rather than unnecessary costs.

Aesthetic Appeal

Aesthetic appeal plays an essential role in how products are perceived in the market. When you take into account gold plating, it greatly enhances the visual attractiveness of items, making them more desirable. The rich, lustrous gold color is a standout feature, and its ability to create various color variations allows you to customize products for specific markets or consumer preferences. This versatility is particularly appealing in jewelry, where different shades can evoke different emotions or styles.

Moreover, gold plating offers texture enhancement, adding depth and sophistication to surfaces. The smooth, reflective quality of gold can elevate a product's perceived value, making it look more luxurious. This effect can be particularly beneficial for items like electronics or fashion accessories, where first impressions matter immensely.

However, it's vital to balance aesthetics with functionality. While gold plating can make products visually striking, you need to take into account how it affects overall performance and longevity.

Ultimately, the aesthetic appeal of gold plating can greatly influence consumer choices, but you must guarantee that it aligns with the product's intended use and target audience.

Corrosion Resistance

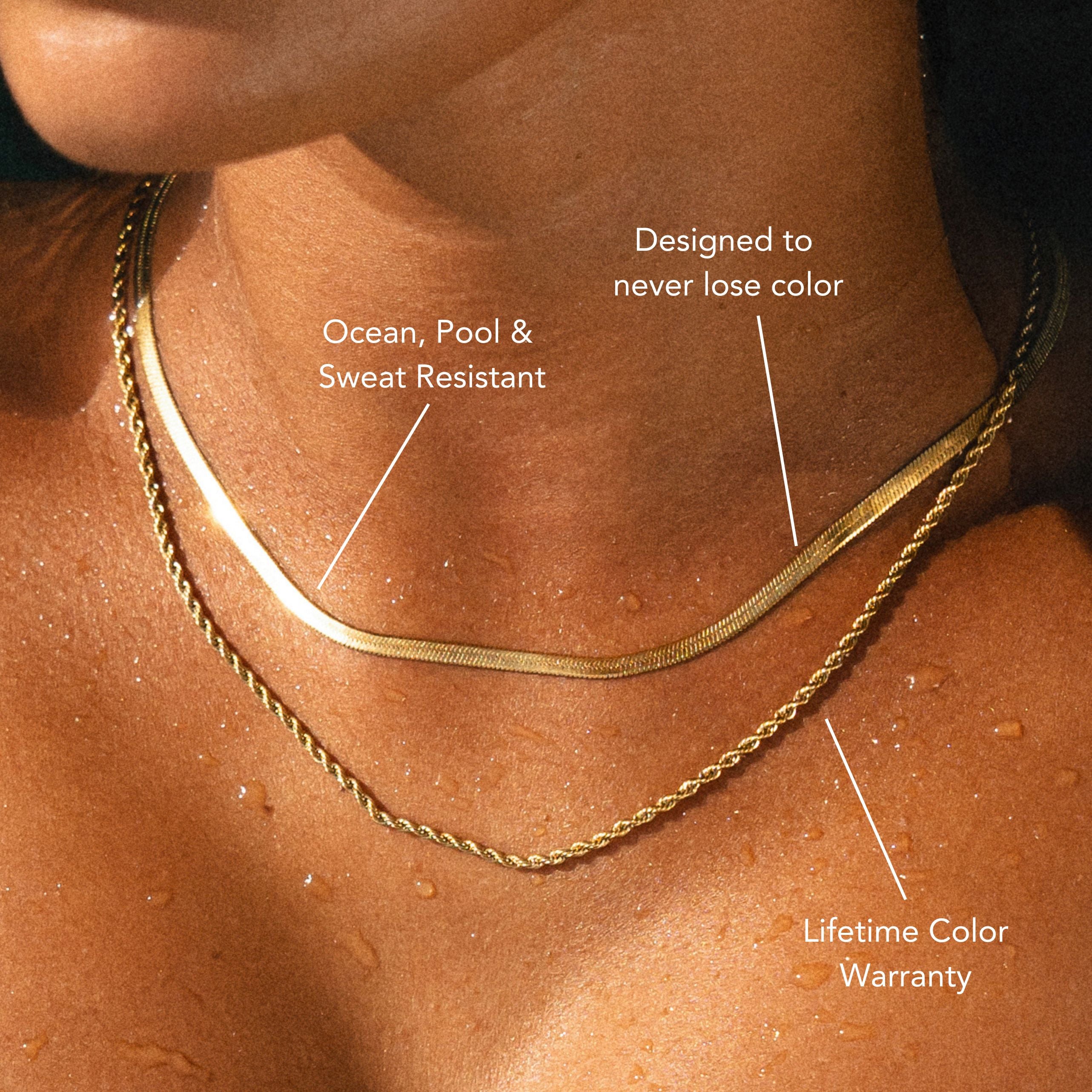

When it comes to durability, corrosion resistance is a noteworthy advantage of gold plating. Gold is inherently resistant to oxidation and tarnishing, which means that it can effectively protect underlying materials from environmental factors that typically cause corrosion. This property makes gold plating an excellent surface treatment for items exposed to moisture, air, and other corrosive elements.

By applying a thin layer of gold over metals like copper or silver, you can enhance their longevity considerably. The gold acts as a barrier, providing corrosion prevention that prolongs the life of the underlying substrate. In industrial applications, this aspect is particularly essential, as equipment and components often face harsh conditions that can lead to rapid deterioration.

Moreover, gold plating isn't just about aesthetics; its corrosion resistance contributes to the reliability and functionality of the products. This is especially important in sectors such as electronics and jewelry, where performance and appearance are paramount.

While gold plating does require maintenance over time, the corrosion resistance it offers can lead to reduced repair costs and improved performance, making it a practical investment for many applications.

Electrical Conductivity

In the domain of electrical conductivity, gold plating stands out for its exceptional ability to facilitate efficient electrical connections. When you compare the conductivity of gold to other metals, you'll find that it offers superior performance, primarily due to its high electron mobility. This quality makes gold an ideal choice for applications where reliability and low resistance are paramount.

In conductivity comparisons, gold alloys often show varied performance based on their composition. While pure gold exhibits the highest conductivity, the addition of other metals can enhance certain properties like hardness and durability, albeit at the expense of some conductivity. For instance, gold-plated connectors often incorporate nickel or copper to provide additional strength, but this may slightly reduce the overall conductivity.

Moreover, gold's resistance to oxidation guarantees that the conductive pathways remain intact over time, minimizing signal degradation. This longevity makes gold plating particularly advantageous in high-performance electronics, where maintaining consistent electrical performance is critical.

Consequently, while gold may not always be the most cost-effective option, its unparalleled conductivity and reliability make it a valuable choice in many applications.

Cost Considerations

While gold plating offers notable advantages regarding electrical conductivity, it's important to take into account the cost implications associated with its use. Conducting a thorough cost analysis is essential before deciding to employ gold plating in your projects.

The primary expense involves the material itself, as gold is a precious metal with fluctuating market prices. Additionally, the costs for the plating process and any required surface preparation can add up quickly.

When considering your pricing strategies, it's vital to factor in these expenses to maintain profitability. If you're working on a large-scale production, the cumulative costs can greatly impact your budget. It's advisable to analyze whether the benefits of gold plating outweigh the expenses in your specific application.

Moreover, you should be aware of the potential for cost-saving alternatives, such as using less expensive coatings that may provide acceptable conductivity, albeit with certain trade-offs.

Ultimately, understanding both the upfront and long-term costs associated with gold plating will help you make informed decisions that align with your financial objectives.

Durability Factors

Durability is a critical evaluation when assessing gold plating for applications where longevity and performance are essential. When you choose gold plating, you should assess its wear resistance and scratch resistance to determine how well it will withstand daily use.

Gold plating typically offers a superficial layer of gold over a base metal, which can enhance aesthetic appeal but may compromise durability depending on the thickness of the gold layer.

In terms of wear resistance, gold plating can perform well in low-abrasion environments, but in high-wear applications, it mightn't hold up as effectively. Thinner layers are more prone to wear, leading to quicker degradation over time. If your application involves frequent handling or friction, you may find that gold plating wears away faster than alternatives like solid gold or other durable coatings.

Scratch resistance is another factor to evaluate. While gold itself is a relatively soft metal, the underlying substrate can influence the overall scratch resistance of the plated item.

In situations where scratches are a concern, you may need to weigh the benefits of gold plating against the potential for surface damage, as this could impact both appearance and functionality.

Applications of Gold Plating

In various industries, gold plating serves multiple practical applications due to its unique properties.

In jewelry applications, gold plating enhances aesthetic appeal while also providing a protective layer against tarnishing. This process allows you to achieve a luxurious look without the high cost of solid gold, making it a popular choice for fashion jewelry and accessories.

In the domain of electronics, gold plating is vital for electronic components. Its excellent conductivity and resistance to corrosion guarantee reliable performance and longevity in connectors, circuit boards, and other critical parts.

By using gold plating, you can improve the efficiency of electronic devices, since gold minimizes electrical resistance and enhances signal quality.

Additionally, gold plating finds uses in medical devices and automotive parts, where reliability is of utmost importance. Its biocompatibility makes it suitable for various medical applications, while its durability benefits automotive industries by preventing wear on essential components.

Frequently Asked Questions

Can Gold Plating Be Removed or Repaired Easily?

You can remove gold plating, but it often requires specialized techniques to avoid damaging the underlying material. Plating repair is possible, yet it may not restore the original quality, so caution is essential during the process.

What Industries Rely Heavily on Gold Plating?

You'll find that electronics manufacturing and jewelry design heavily rely on gold plating. In electronics, it enhances conductivity and corrosion resistance, while in jewelry, it provides an attractive finish that maintains aesthetic appeal without sacrificing durability.

How Does Gold Plating Compare to Other Plating Techniques?

When comparing gold plating to other techniques, you'll find its superior electrical conductivity and corrosion resistance stand out. While alternatives may offer cost benefits, they often lack the long-term durability and performance gold plating provides.

Is Gold Plating Hypoallergenic for Sensitive Skin?

Gold plating can be hypoallergenic, depending on gold purity and underlying materials. If the base metal contains nickel or other irritants, you might experience skin irritation. Always check for quality to minimize potential reactions.

Conclusion

In conclusion, while gold plating offers numerous benefits like aesthetic appeal, corrosion resistance, and excellent electrical conductivity, it is crucial to weigh these advantages against its drawbacks, including cost and potential environmental impact. If you're considering gold plating for a project, you'll need to evaluate your specific needs and explore alternatives that might provide similar benefits at a lower cost or with less environmental concern. Ultimately, making an informed decision can lead to better outcomes in your applications.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.